Whitepaper - Trends in High Temperature Alloys

White Papers

Trends in High Temperature Alloys

Modern high temperature alloys have undergone little change in chemical composition in the past thirty years. Most possible combinations of iron, nickel, cobalt, chromium, molybdenum, tungsten, titanium, aluminum, columbium and trace elements have been evaluated, leaving slight opportunity for "new" alloys. The existing alloys are much improved, however.

Recent improvements in alloy performance capability have been achieved primarily through processing enhancements. This article discusses the results obtained by improved processing techniques, after first updating the major high temperature alloy families and their service capabilities.

High temperature alloys broadly refer to those materials which provide strength, environmental resistance and stability within the 500°F (260°C) to 2200°F (1205°C) temperature range. They have been used generally in the presence of combustion from heat sources such as turbine engines, reciprocating engines, power plants, furnaces and pollution control equipment.

These alloys must employ a strengthening mechanism to impart the desired strength at maximum exposure temperature. Therefore, the alloy microstructure must remain stable at the operating temperature.

The stability requirement represents a constant challenge to designers of parts and components. To achieve desired properties, metals are usually heat treated to a metastable condition which reverts to a less useful equilibrium structure upon elevated temperature exposure.

Therefore, it is critical that designers understand and document expected operating conditions. Special consideration should be given to aggressive environments which compound the effects of elevated temperatures.

From a competitive standpoint, alloy selection must be based on expected cost effectiveness. The best choice usually will be the lowest cost material able to meet design criteria. A higher cost material offering greater reliability may be justified, however, for certain components in a system that is critical and/or ex- pensive to shut down for maintenance. Knowledge of alloy capabilities can be helpful in making a wise decision.

Four Alloy Groups

High temperature alloys can be categorized into four distinct groups based on matrix composition.

Iron-Base Alloys - This group comprises the low chromium alloys such as 3Cr-1Mo-V, 4340 alloy, CarTech AerMet®100 alloy and Maraging 250, to the 12% chromium, martensitic stainless steels which include CarTech 636 alloy, CarTech Greek Ascoloy (AMS 5616), CarTech H-46, CarTech Jethete M152, FV535 and 355.

The latter group is sometimes referred to as Super 12 Chrome steels with refractory elements such as molybdenum and tungsten to provide greater strength at elevated temperatures. Other minor element additions such as vanadium, columbium and nitrogen are also made for strengthening purposes. The iron-base, low-chromium, marten- sitic steels can be used at temperatures up to 750°F (400°C) while the 12% chromium martensitics may be used at temperatures up to 1200°F (650°C), but provide only moderate strength above 1000°F (540°C).

Other grades in this group include the more highly alloyed exhaust valve steels such as AMS 5700 (aircraft) and the 21-23% chromium manganese alloys with the commercial designations 21-2N, 21-4N, 21-12N and 23-8N. The latter three grades are age hardenable. The age hardening, engine valve type grades are used up to 1400°F (760°C), but provide fairly low strength at the upper end of their temperature capability.

Iron-Nickel Base Alloys - Both non-age hardenable and age harden- able grades are included in this category. Type 330 stainless and N-155 are examples of solid solution-strengthened (non-age hardenable) alloys.

Age hardenable grades include CarTech A-286, CarTech 901, CarTech V-57, CarTech 706, CarTech CTX-1, CarTech CTX-909 and CarTech Thermo-Span® alloys. All of these alloys contain columbium and/or titanium, and aluminum to promote age hardening. Good strength and hardness are obtained in the 1100°F (595°C) to 1300°F (705°C) range when these alloys are solution treated and aged.

Nickel-Base Alloys - These alloys contain more nickel than iron. Chromium is in the range of 20%, and nickel ranges between 50 and 80%. Other alloying elements include molybdenum, tungsten, aluminum, titanium, columbium, cobalt and boron.

This group includes both age hardenable grades and solid solution-strengthened grades (non-age hardenable). Typical of the age hardenable alloys are: CarTech Waspaloy, M-252 and CarTech 41, 80A, 718, 90, X-750 and 751, which are used at temperatures up to 1600°F (870°C). Solid solution-strengthened grades (CarTech 102, 680 and 625) see service at temperatures up to 2200°F (1205°C), where precipitation strengthening is no longer useful.

Cobalt Base Alloys - Typical of this category is CarTech L-605 alloy which contains 50% cobalt in addition to nickel, iron, chromium and tungsten. It is a ductile alloy suitable for service up to about 1900°F (1040°C). Other examples include MP159 and CarTech 188 alloys. Metals in this group are particularly useful in sulfur-bearing environments where nickel-base alloys are readily attacked.

Alloy Cost VS Capability

As temperature and strength requirements increase, so does the necessary alloy content. Iron-base martensitic alloys are most commonly used in the 500° - 1000°F (260° - 540°C) temperature service range. Much above 1000°F (540°C), the martensitic alloys (i.e. - CarTech H-46, CarTech 636, CarTech Greek Ascoloy) tend to over temper to an unacceptably low strength for many applications. These alloys are economical, however, due to their high iron content. They generally are the most cost effective in this temperature range.

Higher strength can be provided by ultra-high strength materials like maraging steels and CarTech AerMet 100 alloy, but these grades are not recommended for service above 750°F (400°C).

Precipitation hardened alloys dominate high strength applications in the 1000 - 1500°F (540 - 815°C) temperature range. These alloy systems consist of an austenitic matrix strengthened by precipitates of nickel and aluminum, titanium or columbium (Ni3 Al, Ni3 Ti, Ni3 Cb) and solid solution-strengthening elements such as molybdenum.

The temperature limit for these alloys is reached when the precipitates start to overage and dissolve. Heat resistance can be improved, however, by increasing precipitate-forming elements (Ti, Al, Cb). Nickel also must be increased continually to form the intermetallic precipitates and to stabilize the austenitic structure given the higher alloy content.

Cobalt, too, may be added to reduce the solubility of precipitates. So may refractory elements tungsten and molybdenum be added to increase high temperature stiffness. All of these additions, made to improve temperature capability, add significantly to the cost of the alloy.

Alloy Selection Criteria

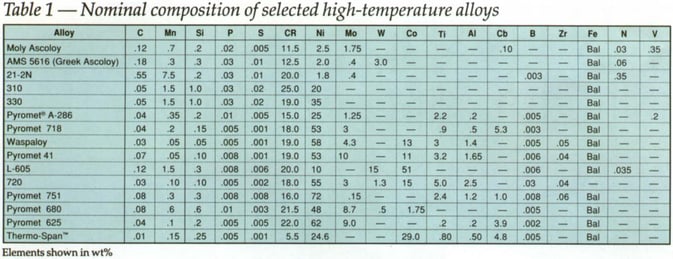

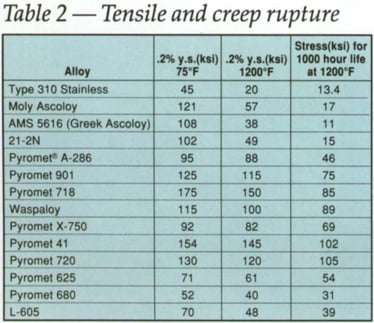

Alloy selection is dependent on mechanical property requirements (i.e. - strength, creep, fatigue) as well as the maximum exposure temperature. Compositions, mechanical properties and practical service limits of typical high temperature alloys are shown in Tables I, II and III, respectively.

Alloy selection is dependent on mechanical property requirements (i.e. - strength, creep, fatigue) as well as the maximum exposure temperature. Compositions, mechanical properties and practical service limits of typical high temperature alloys are shown in Tables I, II and III, respectively.

CarTech A-286 alloy occupies the "low end" of the austenitic precipitation hardening high temperature alloys. It has moderate strength capabilities and long term service capability up to 1150°F (620°C). With a nominal 25% nickel content, it can be quite cost effective.

Other commonly used alloys, in ascending order of temperature capability, include CarTech 901, CarTech 718, CarTech X750, CarTech 751, CarTech Waspaloy, CarTech 41 and CarTech 720 alloys. Table I illustrates the increasing alloy content in this series of materials.

Pyromet® 718 alloy, perhaps the most universal high temperature alloy, accounts for the largest percentage of total industry "superalloy" production. It possesses high strength and creep resistance up to 1250°F (675°C), and a reasonable level of both properties up to 1400°F (760°C). Its fatigue properties are excellent. Large scale production makes this alloy more economical than the composition might suggest.

CarTech Waspaloy begins to dominate when temperatures exceed 1250°F (675°C) and when superior creep properties up to 1400°F (760°C) are needed. Higher nickel and cobalt contents result in greater cost. Waspaloy is a good candidate for applications ranging from turbine components and fasteners to forging dies.

Rene 41 offers service capabilities beyond Waspaloy because of its higher titanium, aluminum and molybdenum contents. It has been used in fastener applications up to 1600°F (870°C), but is better suited to the 1350°F (730°C) to 1500°F (815°C) range. It has higher strength and creep resistance than Waspaloy, but slightly less fatigue resistance.

The 720 alloy serves in the same temperature range as Waspaloy and Pyromet® 41 alloy while providing strength and creep resistance superior to both. Its high alloy content is at the practical upper limit for conventionally cast and wrought alloys, and is therefore more costly and difficult to produce. Alternative alloys are gener- ally more cost effective if they possess the necessary properties.

Controlled thermal expansion alloys are an important family within the precipitation hardening group. These special purpose materials provide low coefficients of thermal expansion within their intended service temperature ranges: -40°F to 1250°F (-40°C to 680°C).

Typical alloys in this family are Pyromet® alloys CarTech CTX-1, CarTech CTX-3, CarTech CTX- 909 and CarTech Thermo-Span alloy. They rely on a chromium-free or low-chromium, nickel-iron-cobalt matrix which is austenitic yet ferro- magnetic to provide low expansion characteristics. These alloys are prone to oxidation above 1000°F (540°C), but provide unique capabilities in sealing and thermal fatigue-limited applications.

The precipitation strengthening mechanism is relatively ineffective above 1600°F (870°C) because precipitates overage and become unstable, causing loss of integrity. Solid solution strengthened alloys dominate in the upper temperature range.

Solid solution strengthening consists of alloying a matrix with elements having large atomic diameters - such as molybdenum and tungsten in a nickel-chromium or nickel-cobalt-chromium matrix. The large atoms stiffen the material, providing creep resistance; however, these materials cannot be strengthened to the levels of precipitation hardening alloys.

The lowest cost materials suitable for temperatures above 1600°F (870°C) are the 300 series stainless steels. While they provide only low levels of strength, some grades possess sufficient environmental resistance for continuous service as high as 2100°F (1150°C).

The three best choices, in order of increasing capability, are CarTech 309, CarTech 310 and CarTech 330 stainless steels. Exposure of CarTech 309 and CarTech 310 at 1600°F (870°C) will cause sigma phase embrittlement, making CarTech 330 the most forgiving of the stainless steels.

Higher strength capabilities can be found in more highly alloyed solid solution strengthened metals like CarTech 600, CarTech 601, CarTech L-605, CarTech 680 and CarTech 625, and Alloy S and Alloy 188. Exotic oxide dispersion-strengthened metals can be considered for even more severe service conditions.

Trends in Manufacturing

The scarcity of new heat resisting alloys has not inhibited the drive for improved material and component performance. Alloy users have benefited from alloy producers' improved quality control, cost containment, better homogeneity, tighter inspection limits, greater cleanliness, enhanced workability and improved reliability. Larger diameter product has become increasingly available.

Producers are continually evaluating methods of manufacture, looking for ways to reduce alloy variation, improve yields, reduce cycle times and enhance material characteristics.

Process control has been particularly effective in reducing product variation. Instead of working to specification minimums, some alloy producers and users now prefer to establish and work to upper and lower control limits often above the minimum requirements. This approach enables component designers to design to much higher stress levels while still allowing margins of safety.

Improvements in material grain size and cleanliness also permit tight ultrasonic inspection limits. Ten years ago a 2 mm indication was a common rejection standard. Today a reading of 0.8 to 1.2 mm is a common inspection threshold. Thus designers assume a much smaller flaw size when establishing allowable design stresses. As a result, components can be made lighter in weight, or operate under higher stress conditions.

Process Database

The advent of large statistical databases on mainframe computers has helped Carpenter to significantly improve product quality, consistency and cost effectiveness.

For example, the compositions of hundreds of heats of material can be statistically analyzed for effects on mechanical properties or hot workability. Statistically significant effects are noted and future compositional ranges are adjusted accordingly. In this way, the hot ductility of Waspaloy at forging temperatures has been doubled, easing the production of complex forgings. Carpenter, its forging customers and end users have benefitted.

Process data from melting, preparation, remelting and forging operations is also entered into a mainframe database. When a heat of material exhibits a certain attribute (desirable or undesirable), its data set is compared statistically with the data from other heats. Factors contributing to the attribute are then identified. Then process control limits are established or adjusted to promote or avoid the attributes as desired.

This technique was used to identify factors affecting vacuum arc remelting stability, which ultimately affects homogeneity. Control points were established for the critical primary process parameters and structural uniformity was substantially improved. Similarly, critical hot working parameters were identified and controlled. The net result was finer, more uniform grain structure.

Alloy cleanliness has been upgraded through carefully controlled raw material selection, use of specially designed tundish systems at VIM, inert gas shrouding of ARC-AOD melted materials, improved electrode preparation techniques and better control of remelting parameters. In some cases, triple melting (VIM-ESR-VAR) is employed.

Fatigue characteristics are improved by resultant lower inclusion levels. Yield improvements also have occurred due to reduced hot working defects and lower ultrasonic defect levels.

Improved cleanliness permits more aggressive hot working techniques. Since the cleaner metal is less prone to cracking, much larger work reductions can be made. This capability, coupled with lower finish forging temperatures, produces much finer grain structures. For example, a 14"-dia. CarTech 718 alloy billet can be produced with an ASTM 6 grain size, permitting ultrasonic inspect- ion to 50% of 0.8 mm defect levels.

Combined with enhanced remelting control systems, improved cleanliness also promotes VAR stability. Larger ingots can be produced with homogeneity comparable to that in smaller ingots. Traditionally, many superalloys were limited to 20"-dia. ingots due to segregation tendencies. Today, alloys such as CarTech Waspaloy are routinely produced in 30"-dia. ingots.

Forging Processes

Various forging processes are now combined to maximize billet and bar quality. Carpenter's 3,000-ton press, for example, is used to break up cast ingot structures. Material then can be transferred to an SX-65 rotary forge, the largest in North America. Numerous large reductions can be made without reheating the product. Efficiency is very high compared with conventional forging, and finer grain sizes can be achieved. The SX-65 rotary forge can also convert ingot directly to billet and bar with great efficiency if coarser grain sizes are permissible.

Carpenter recently installed a smaller SX-32 rotary forge in line with the SX-65. The SX-32 can produce finish sizes in the 2.5" to 6" range, thus freeing the larger forge to concentrate on sizes above 6", where throughput is greater. This tandem arrangement also permits the conversion of ingot to smaller bar and billet in a single day, substantially reducing cycle times.

Complementing the forge lineup is a state-of-the-art bar mill for production of sizes down to about 1/2", and a wire mill for making smaller diameter coils down to 1/4". Further size reductions can be made by cold drawing.

Mechanical Test Reduction

The elimination of unnecessary testing could help the industry to further reduce cycle time and costs. Current testing requirements for high temperature alloys are defined in general industry specifications (ASTM, AMS), as well as in user specifications.

Many of these requirements were established in the 1960's when production practices were yet to be refined. Today the industry is burdened with a plethora of test conditions and parameters which are unnecessary, given current process controls. A single order made to multiple specifications may undergo as many as 30 separate mechanical and microstructural tests. This procedure extends cycle times and creates unnecessary costs.

The stress rupture test, used to measure high temperature creep properties, is one example. Tests consuming hundreds of hours may be required at numerous temperatures, stress conditions and specimen configurations. In reality, creep resistance can be assured without testing if compositional, microstructural and elevated temperature tensile control limits are met.

One major turbine manufacturer, drawing the same conclusion, has eliminated the test for some materials. The rest of the industry has been slow to follow suit. In perspective, one might view the elimination of unnecessary testing requirements as "low hanging fruit".

Another example is magnetic particle testing of raw material, even though rejections to AMS 2300 and 2303 are almost non-existent. Concurrently, the ASTM E-45 metallographic inclusion test is more sensitive, conserves material and is loss costly to perform. How- ever, magnetic particle testing of ferro-magnetic materials remains the rule rather than the exception.

It is time for the industry to re-examine these requirements. Product integrity can be assured by requiring only macrostructure, microstructure and elevated temperature tensile testing - if a producer can demonstrate narrow limits of compositional control, as well as melting, remelting and hot working controls.

Conclusion

The selection of cost-effective alloys for high temperature service depends on knowledge of service requirements and materials capability. Each temperature regime offers several alloy options, depending on mechanical property and environmental resistance requirements.

High temperature alloys have reached a state of maturity in which tailoring existing alloys to specific needs takes precedence over alloy development. Alloy processing techniques and controls have advanced dramatically, leading to new thresholds of alloy performance.

User needs have been met through reduced cycle times, improved delivery reliability and cost control. A major opportunity now exists for the industry to benefit further by applying statistical principles to test reduction efforts.

***

By Kurt P. Rohrbach

Marketing Manager - Turbine Materials

Carpenter Technology Corporation

Reading, PA

USA