Custom 465® High Strength Stainless Steel

Technical Guide

Reliability has become the cornerstone of the materials selection process in the aerospace industry. Aircraft are now expected to remain in service for up to 30 years or longer, with minimal maintenance.

Thus, structural components such as flap tracks, actuators, engine mounts, landing gear hardware and the like are candidates for upgraded alloys (Fig. 1).

Certainly, corrosion and associated stress corrosion cracking (SCC) are major mechanisms that degrade the reliability of these components over the extended life of modern aircraft. Stainless steels, particularly high-strength precipitation-hardened stainless alloys, must be considered for parts operating in rather severe environments.

It has been suggested that any new high-strength PH stainless alloy should have an overaged tensile strength of about 240 ksi (1655 MPa), along with resistance to SCC equivalent to that of PH 13-8 Mo[1] in the H1050 condition (190 ksi or 1310 MPa tensile strength).

Custom 465® stainless is a new alloy designed to meet these demanding requirements. This is a premium melted, martensitic, age-hardenable stainless steel that, when overaged to the H1000 condition, provides a superior combination of high strength, fracture toughness, and resistance to stress corrosion cracking compared with other high-strength PH stainless alloys such as Custom 455® stainless or PH 13-8 Mo stainless.

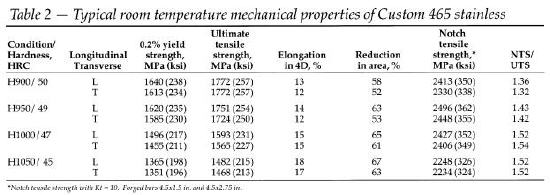

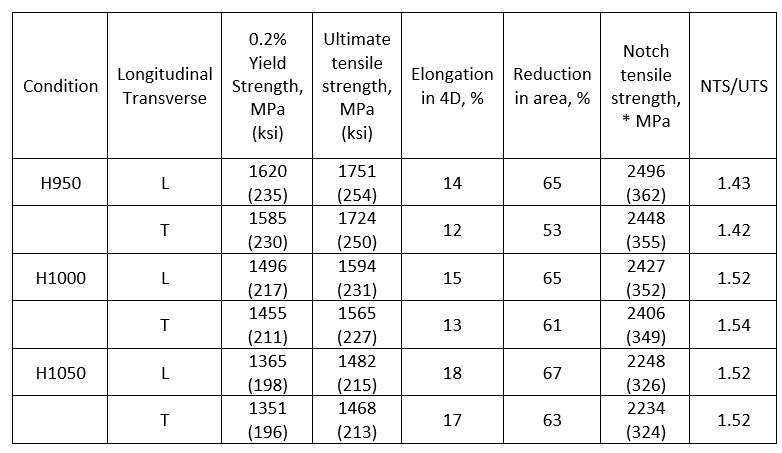

Mechanical Properties

Typical room temperature mechanical properties for Custom 465 stainless can be seen in Table 2. Custom 465 stainless is capable of about 260 ksi (1795 MPa) ultimate tensile strength if peak aged (H900 condition). In this condition, it still retains high notch tensile strength and fracture toughness.

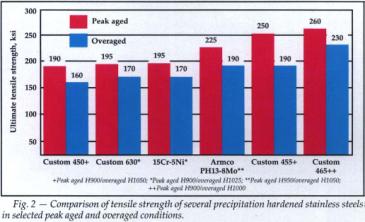

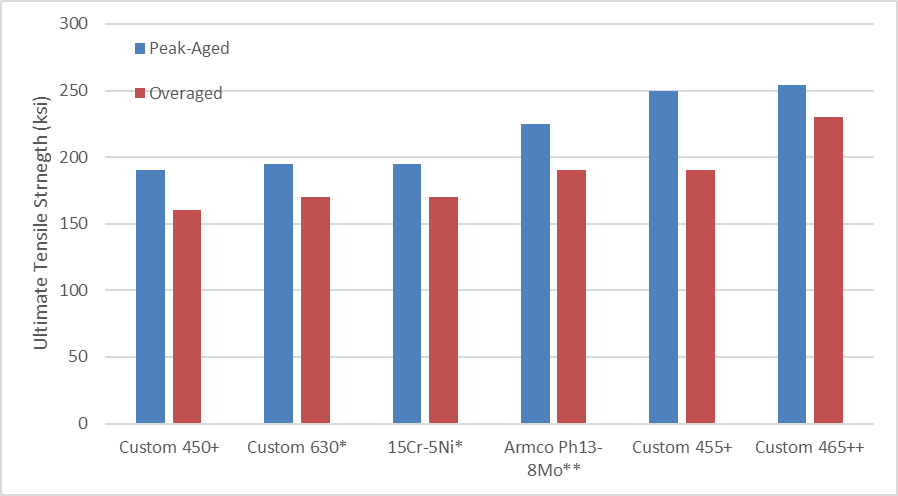

The H950 through H1000 aging conditions are suggested for most applications to capitalize on the alloy's higher strength capability. Incremental aging temperatures up to 1150°F can be used to provide other combinations of properties. The peak aged and overaged tensile strength of Custom 465 stainless and several other PH stainless steels are shown in Fig. 2. The new alloy has higher strength than the other alloys in both conditions.

In general, the steel is less sensitive to process parameters than other high-strength PH stainless steels. Its relatively low annealed yield strength, along with a low cold work hardening rate, make the alloy conducive to forming fasteners and drawing small diameter wire. For example, Custom 465 stainless can be cold drawn in excess of 90% reduction, with no intermediate anneal. On the other hand, drawn and aged wire of the material has achieved a strength of more than 300 ksi (2070 MPa).

Custom 465 stainless has exhibited excellent thermal stability when exposed long term to elevated temperatures. Testing found only minimal changes in ultimate tensile strength and notch tensile strength when samples were heat treated to the H1000 condition, then held for 1,000 hours at temperatures from 600°F to 900°F.

Corrosion Resistance

General corrosion resistance of Custom 465 stainless approaches that of 304 stainless. Exposure to 5% neutral salt spray at 95°F (35°C)(per ASTM B117) caused little or no rusting after 200 hours regardless of condition (i.e., annealed or H900-H1100 conditions).

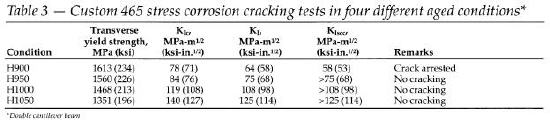

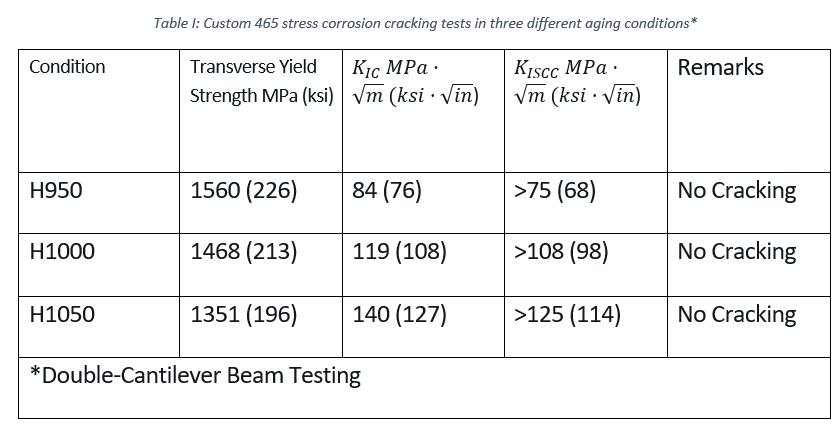

Double-cantilever-beam tests conducted in 3.5% NaCl (pH 6), at room temperature, show that Custom 465 stainless possesses inherently good resistance to stress corrosion cracking in the over-aged condition. That resistance, furthermore, improves (i.e. - the KIc increases) with increasing aging temperature (Table 3).

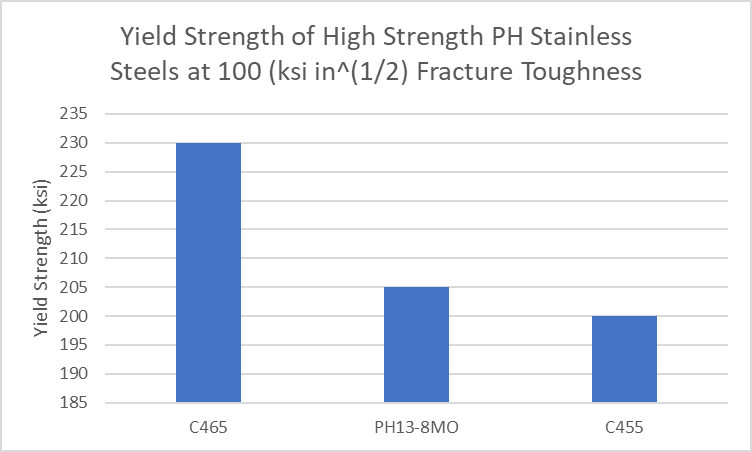

The resistance of Custom 465 alloy to SCC is considered (a) comparable to that of 13Cr-8Ni and Custom 455 stainless, but at significantly higher strength, and (b) superior to that of both of them at the same strength. For example, if one compares the yield strength for each of these three alloys if heat treated to a longitudinal fracture toughness of 100 ksi sqrt(in) (110 MPa sqrt(in)), they can be ranked as follows:

Alloy

Custom 465 stainless

13Cr-8Ni stainless

Custom 455 stainless

Yield Strength*

230 ksi (1585 MPa)

205 ksi (1413 MPa)

200 ksi (1380 MPa)

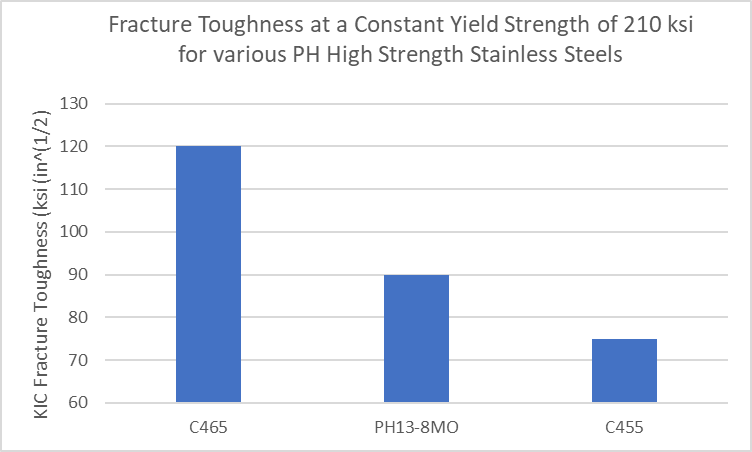

At this level of fracture toughness, the KIscc is essentially equivalent to the KIc for these alloys. On the other hand, if one chooses to consider KIc at a fixed yield strength of 210 ksi (1447 MPa), the ranking is:

Alloy

Custom 465 stainless

Custom 455 stainless

13Cr-8Ni stainless

Longitudinal Fracture Toughness*

120 ksi sqrt(in) (132 MPa sqrt(in))

90 ksi sqrt(in) (99 MPa sqrt(in))

75 ksisqrt(in) (82 MPa sqrt(in))

As a candidate for aerospace applications, Custom 465 stainless can develop significant resistance to chloride SCC by aging at 950°F or higher. This resistance is achieved at strength levels well in excess of those possible with other PH stainless steels. Indeed, the UTS of the new alloy is higher than any other PH stainless in any aged condition from H900 to H1150.

Heat Treatment

The PH stainless is designed to be fully solution annealed at 1800°F±15°F (982°C±8°C), held one hour at heat, and cooled rapidly. Annealing at this temperature makes the aged properties of the alloy less sensitive to prior processing.

Sections up to 7" (180 mm) can be quenched in a suitable liquid, and sections over 7" (180 mm) should be cooled rapidly in air. For optimum aging response, solution annealing should be followed by cooling to -100°F (-73°C), holding 8 hours, then warming to room temperature. Sub-zero cooling should be performed within 24 hours of solution annealing.

The high strength levels of Custom 465 stainless are derived from a single age hardening step consisting of heating to a selected temperature between 900 and 1150°F (482/621°C), holding for four hours, followed by air cooling. The choice of aging temperature will depend upon the desired combination of strength, toughness, and SCC resistance desired.

Although the alloy typically is machined in the annealed/cold treated condition, optimum machinability of Custom 465 stainless can be achieved by overaging to the H1150M condition. Material is heated to 1400°F±15°F (760°C±8°C) for two hours, air cooled, then reheated to 1150°F±15°F (621°C±8°C) for four hours and air cooled. If this practice is used, parts must be re-annealed at 1800°F (982°C), cold treated at -100°F (-73°C), and aged at a selected temperature.

The aging flexibility provided by this alloy, and the great range in properties obtainable, make the material a candidate for important applications both within and beyond the aerospace industry.

Cold working the alloy before aging at 900°F, for example, provides maximum strength in excess of 300 ksi for small diameters (d <0.75 in. or 20 mm). This is a strength useful for the manufacture of surgical and dental instruments, and needle wire for the medical industry. With the right combination of strength, hardness and toughness, obtained by proper aging, the material might be used for the cutting edge of hand tools, or for the body of the tool itself.

Custom 465 stainless could be considered as an upgrade for alloy steel parts and components that are currently cadmium or chromium plated. It might also be considered for parts, currently made of 15Cr-5Ni or Custom 630® (17Cr-4Ni) PH stainless steels that could benefit from higher strength, smaller size, and/or lower weight.

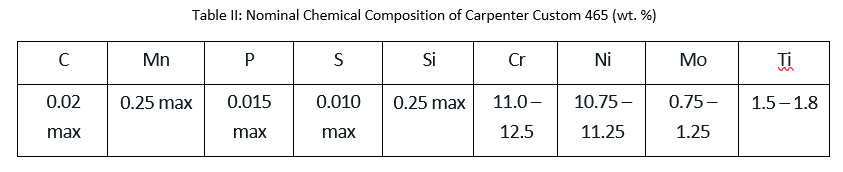

Nominal chemical composition of Custom 465 stainless is shown in Table II:

This material is available in a wide range of product forms from 12" billet and bar to 0.070" wire, and finer. It also can be made in narrow strip and foil. Most product forms are supplied from the mill in the solution annealed/cold treated condition ready for the one-step hardening treatment; billet product is provided in the hot-finished condition.

1 Trademark of Armco, Inc.

* Certain values obtained by interpolation between published values of yield strength or fracture toughness