The Power of

Advanced Electrification

Electrification

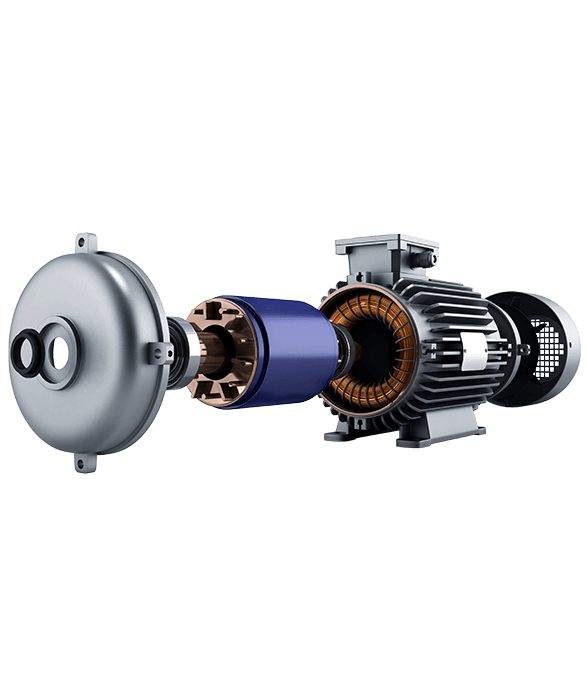

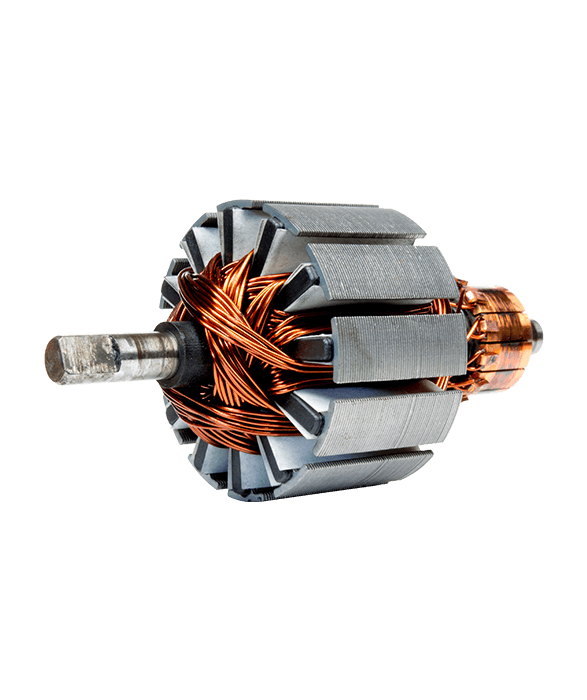

Enabling the Higher Power Density Motors

Advanced soft-magnetic alloys and stack production are transforming the profiles and capabilities of torque-dense electric motors. With every advance in this rapidly changing field, new applications become possible, helping our customers achieve performances that were impossible just a few short years ago.

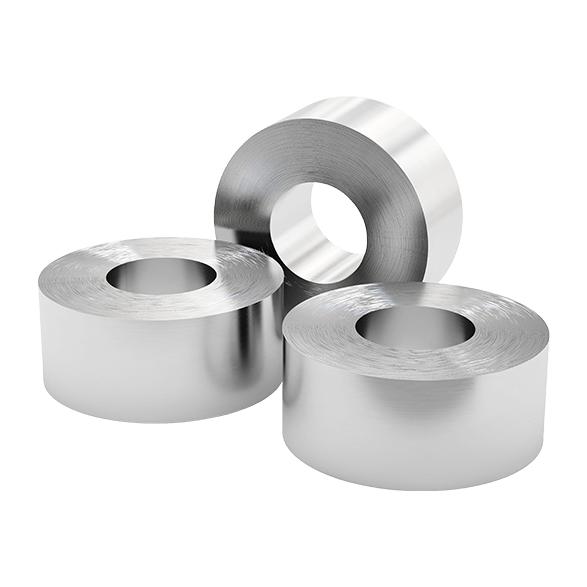

Soft Magnetic Alloys

Your best global partner to scale to production with the largest vacuum induction melting capacity and state-of-the-art hot rolling mill for high-performance soft magnetic alloys.

Learn More

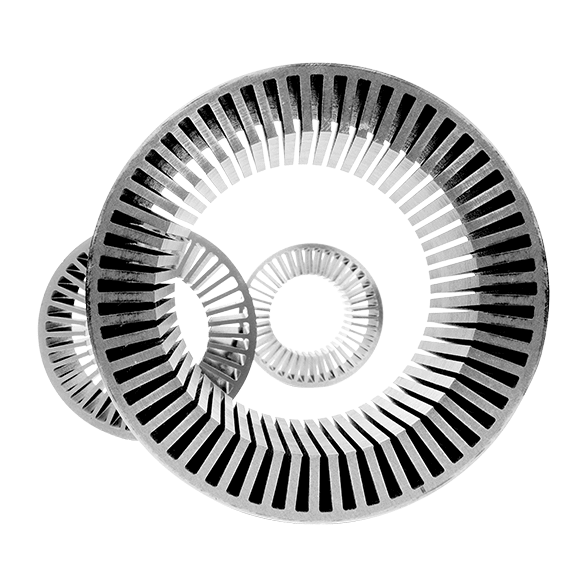

Stator and Rotor Stacks

Engineered, validated, scalable production processes directly from the material experts for optimal lamination and stack performance.

Learn More

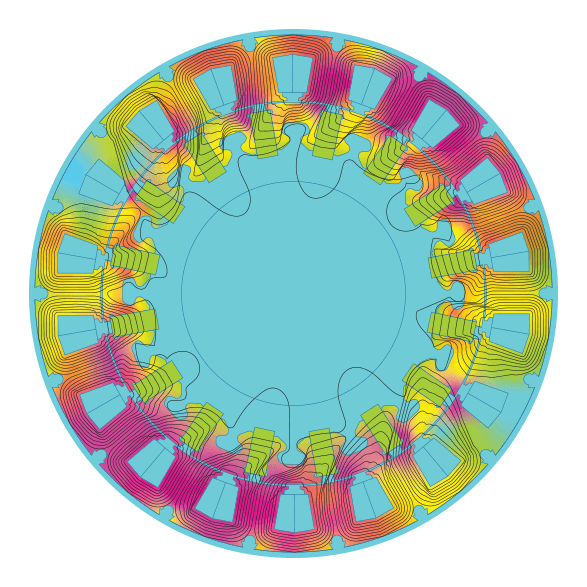

Application Development

End-to-end partnerships with design, integration, modeling, and assembly support for optimal motor power density and performance.

Learn MoreStep into the future of electrification with Carpenter Technology.

Customers call on us when they need to rethink the boundaries of specialty alloys or how our existing top-performance materials can solve new design challenges. We foster long-term relationships to support risk-adverse innovation and explore advanced product applications together

Request a quote today

Elevate your projects performance with our innovative solutions.

APPLICATION SPOTLIGHT

Electrification

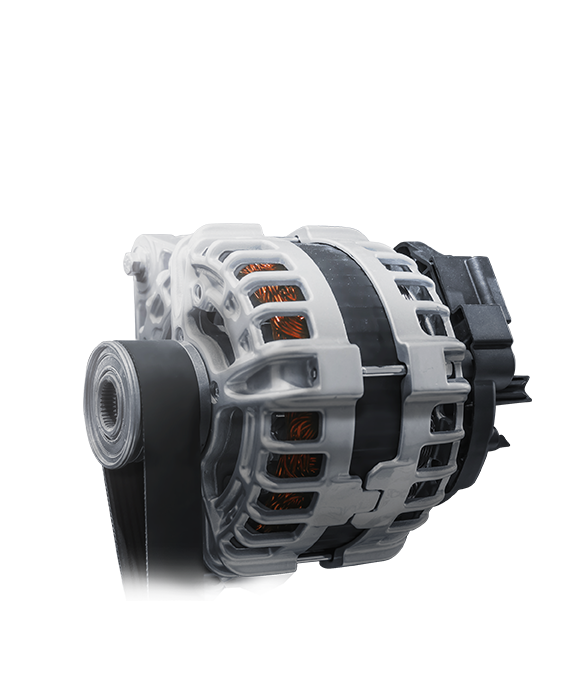

Electric Vehicle Motors

Our soft magnetic alloys allow designers to optimize torque and power density for improved system-level performance by providing 25% higher induction, better permeability, and 30% lower core losses to decrease the motor size up to 30%, without sacrificing torque.

FEATURED PRODUCTS

none

Hiperco® 50A

Highest magnetic induction with the lowest core losses for stator applications in power-dense motors and generators

none

Hiperco® 50

Highest magnetic induction and low core losses with mechanical properties that can be tailored to meet both stator and rotor application needs

Stator and Rotor Stacks

Our expertise in specialized materials and stack processing ensures the highest performance stator and rotor stacks. We have a deep understanding of metallurgical structure-magnetic property relationships and expertise in various processing technologies. Our methods for dimensional control, high-strength, and tailored magnetic properties support the most demanding motor design requirements and production tolerances, resulting in superior motor responses.

FEATURED PRODUCTS

none

Hiperco® 50

Highest magnetic induction and low core losses with mechanical properties that can be tailored to meet both stator and rotor application needs

none

Hiperco® 50A

Highest magnetic induction with the lowest core losses for stator applications in power-dense motors and generators

none

Hiperco® 50HS

Highest magnetic saturation with high yield strength, moderate core loss, and mechanical properties that can help optimize power-dense motors

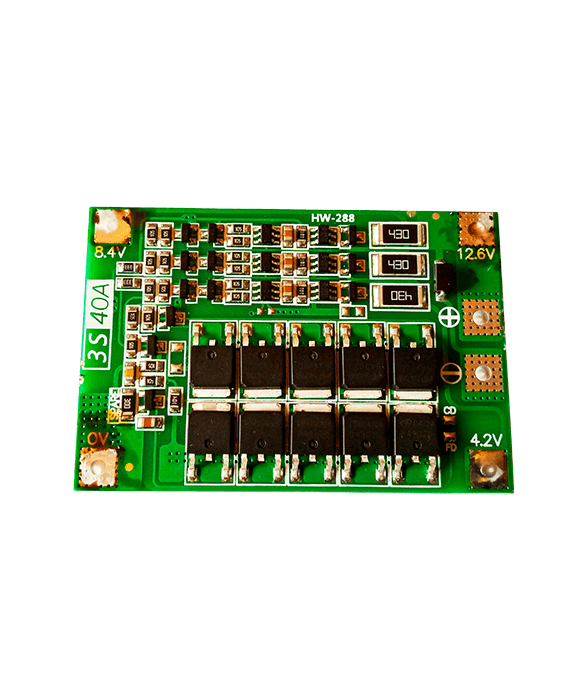

Electric Vehicle Current Monitoring Systems and Battery Management

The battery management system (BMS) is an integral part of electric vehicles and electronic devices where current and voltage monitoring is controlled via resistors. Our materials provide a low temperature coefficient of resistance (TCR) to enable reliable BMS systems.

FEATURED PRODUCTS

none

Evanohm® R

Resistance alloy with low TCR and high thermal stability for more precise regulation of voltage and current for sensors and battery management systems

none

No. 1 JR® (Type 1)

Oxidation-resistant steel with a high specific electrical resistance as well as resistance scale. No. 1 JR has a low temperature coefficient of resistance (TCR)

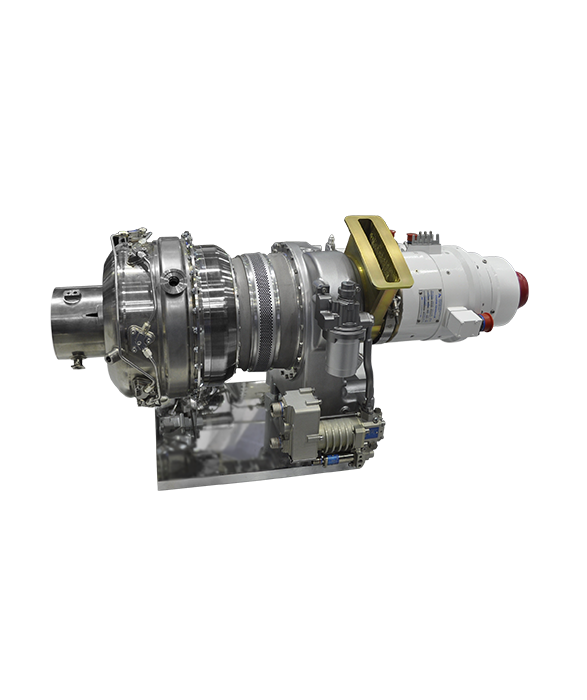

Aerospace Generators and APUs

Higher power and torque delivery facilitate increased power generation. Our high-performance alloys and stator and rotor stacks enable smaller, lightweight designs without compromising on performance.

FEATURED PRODUCTS

none

Hiperco® 50

Highest magnetic induction and low core losses with mechanical properties that can be tailored to meet both stator and rotor application needs

none

Hiperco® 50HS

Highest magnetic induction and high yield strength. Tailored properties can meet demands for power-dense, high-speed motors

Defense Motors and Generators for Vehicle Drives

Military personnel are surrounded by electrical systems requiring increasing power in confined spaces. Maneuverability and efficiency translate to agility and reach and warfighters need to fight from a position of advantage. Our soft magnetic solutions improve the range and acceleration of existing electrical drives.

FEATURED PRODUCTS

none

Hiperco® 50A

Highest magnetic induction with the lowest core losses for stator applications in power-dense motors and generators

none

Hypocore®

Combination of high induction, low core loss, and low coercivity for economical power-dense motors

Consumer Electronic Audio Voice Coils

Our soft magnetic alloy solutions enable designers to reduce the size and weight of electromagnet components within microspeakers in headphones and hearing aids. Material optimization leads to increased performance, such as improved sound pressure level (SPL) and improved battery life for wireless audio devices.

FEATURED PRODUCTS

none

Hiperco® 50

Highest magnetic induction with good permeability and low core losses enabling highly compact designs without sacrificing performance

none

High Permeability 49

High magnetic permeability and good magnetic induction for a combination of fast response with size and weight reduction

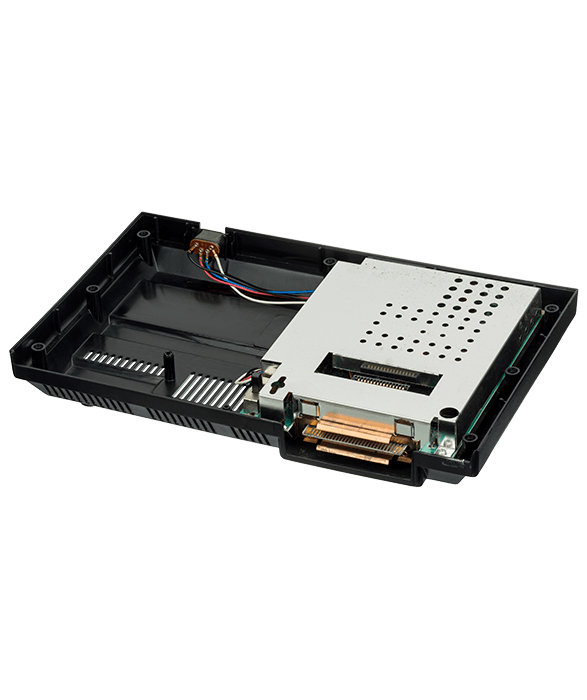

Consumer Electronics Haptics and Micromotors

Haptic actuation devices with micromotors require power-dense solutions allowing torque increase or size reduction. Our soft magnetic alloys offer nearly 40% higher induction and significantly higher permeability, allowing up to 15% higher device acceleration.

FEATURED PRODUCTS

none

Hiperco® 50

Highest magnetic induction with good permeability and low core losses enabling highly compact designs without sacrificing performance

none

Hiperco® 27

High magnetic saturation induction with greater ductility and toughness for applications requiring a combination of good magnetic and mechanical performance

Consumer Electronics Shielding and Flux Focusing

Soft magnetic alloys allow for the suppression, attenuation, and mitigation of magnetic fields. High permeability and high saturation soft magnetic materials can reduce the electromagnetic interference (EMI) in your application to meet electromagnetic compliance (EMC) needs.

FEATURED PRODUCTS

none

HyMu 80

Superior permeability and low core loss. An excellent choice for shielding in electric and acoustic devices, and for ultra-fast response in electric circuits

none

High Permeability 49

High magnetic permeability and good magnetic induction for a combination of fast response with size and weight reduction

Related Resources

Browse our electrification experts' library of resources including white papers, product brochures, technical datasheets, webinars, and more.