defense

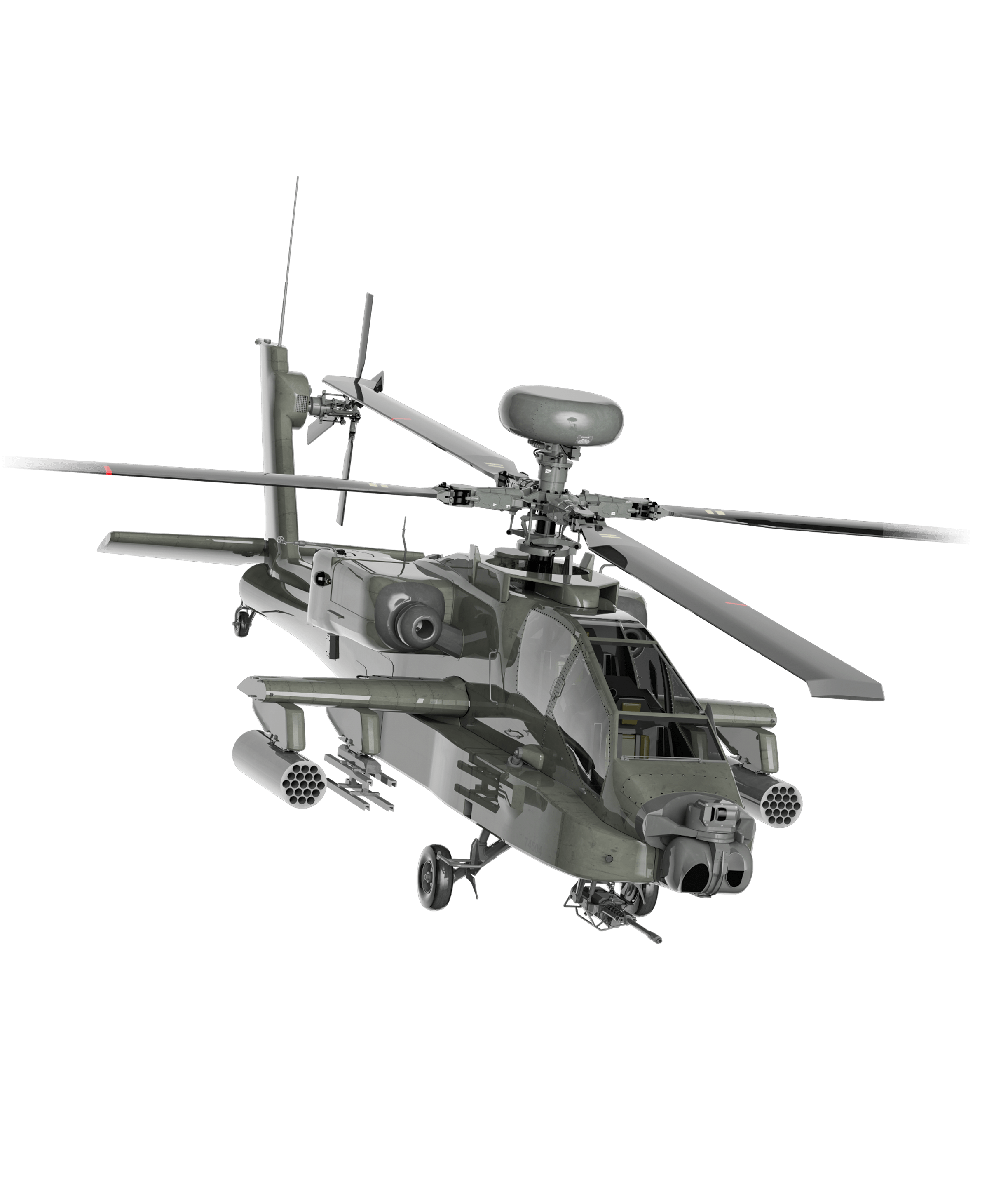

Rotorcraft

Mission Critical Performance

We provide advanced specialty materials for life and flight critical applications. The design challenges of in-the-field applications for defense are unlike any other. Lives, safety, and security depend on exceptional performance and reliability in hostile environments. Whether facing the challenges of high-torque, temperature and pressure changes, corrosive environments, or all of them at the same time, our materials provide designers with the resources they need to design lighter, faster, stronger, and tougher.

APPLICATION SPOTLIGHT

Rotorcraft

Rotor Shafts

High strength and toughness are imperative for the structural alloys used in this critical design component. We offer alloys with the highest strength to ensure peak performance.

FEATURED PRODUCTS

none

Pyrowear® 61

Premium quality high-strength carburizing steel with ultra-high core strength as well as high fatigue strength, temperature resistance, and hardenability

none

4340

Low alloy, nickel-chromium-molybdenum steel can be heat treated to high strength levels with a good combination of ductility and toughness

Main and Auxiliary Motors

Bushing applications require exceptional reliability throughout changes in temperature, pressure, and environment, even as they are exposed to corrosive environments and subject to high stress and heavy loads.

Structural Components

Subjected to salty spray and high-torque, materials on marine helicopters demand the highest performance, reliability, and readiness. We customize material properties to specific applications, delivering high-strength in corrosive environments.

FEATURED PRODUCTS

none

Custom 465®

High-strength stainless steel designed for improved notch tensile strength, fracture toughness, and fabricability with excellent resistance to stress corrosion cracking

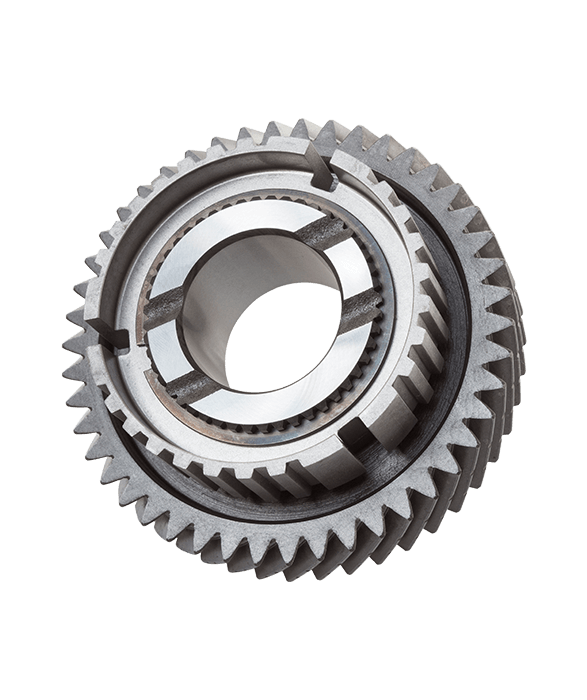

Bearings and Gears

Strength, toughness, and fatigue performance are critical for helicopter gear components that allow them to run at high load-levels without failure. Our materials ensure exceptional performance and reliability in extreme conditions.

FEATURED PRODUCTS

none

Pyrowear® 53

Carburizable alloy for good wear resistance, toughness, and fatigue performance with improved oil out performance

none

Ferrium® C64®

Premium quality carburizing steel with high core strength and higher case hardness for improved wear resistance and improved power density

none

9310

Carburizing steel with high hardenability, good core strength, and superior fatigue resistance, also available in double vacuum melt version

none

M-50

High carbon steel with good wear resistance and fatigue performance

Bolts, Pins, and Fasteners

Strength-to-weight ratio is critical to weight management. Our materials are designed for no-fail situations that include temperature extremes, high pressures, stress and weight loads, and corrosion.

FEATURED PRODUCTS

none

MP35N®

Ultra-high tensile strength, good ductility and toughness, with excellent corrosion resistance that derives its strength from cold working

Work with Carpenter Technology to improve your product and your process.

We develop new materials that can meet or exceed your design parameters and help you achieve performance breakthroughs. This allows you to design smaller and/or lighter with parts and materials that avoid fatigue or fracture. These lighter components can improve performance, increase operating hours and reduce field failures.

Related Resources

Browse our growing library of resources for the market including case studies, product brochures, technical data sheets, product selection guides, and more.