Deformation Modeling Optimizes Metalworking Processes

Market Insights

Author: J. Gonzalez-Mendez

The specialty alloys developed by Carpenter Technology require a high level of expertise across a range of operations, from melting to finishing. Processing must follow strict standards to deliver high-quality products for critical applications in energy, aerospace, automotive, medical, and other essential industries.

Metalworking Design & Optimization

Our research and development group offers a myriad of tools that support all our metalworking operations, including deformation modeling. Thermo-mechanical and microstructural modeling allow the technical team to design and optimize metalworking processes to ensure our products meet strict material properties standards, such as strength, hardness, corrosion, creep resistance, and grain refinement.

Deformation Modeling

Deformation modeling based on Finite Element Analysis simulates the physical phenomena that occur during metal deformation operations, such as forging, rolling, and drawing. Input material properties and process conditions provide an understanding of the transformation that occurs within the material at the thermal, mechanical, and microstructural levels. To provide the valid material inputs for deformation modeling, our R&D group integrates its material characterization capability. One such capability is Gleeble testing, which is an experimental methodology that provides workability information as a function of temperature, deformation, and rate of deformation. This information is then integrated into the deformation modeling software to develop informed models for our metalworking operations.

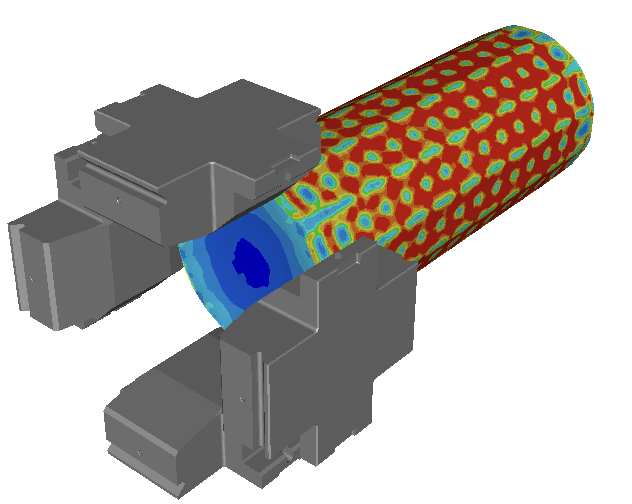

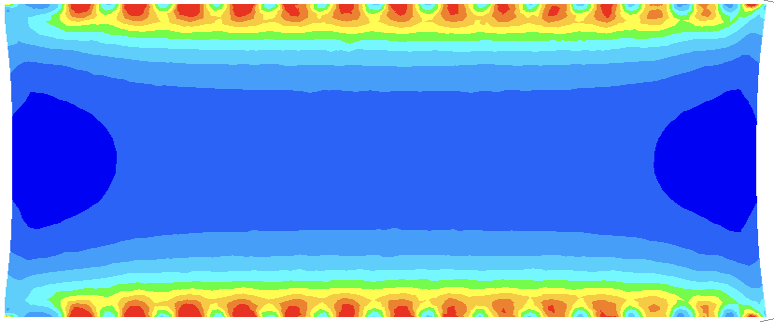

Thanks to the described tools, deformation modeling supports our customers’ needs in a wide range of capacities. For instance, the aerospace industry requires nickel-base alloys such as 718 and Waspaloy with exceptional tensile, creep-rupture, and corrosion properties. Open die forging within the optimal conditions is necessary to achieve these properties. Deformation modeling supports the design of such a forging process by providing information on temperature, strain (Figure 1), and strain rate. With this information, our R&D engineers design a procedure to maintain all deformation conditions within an ideal range. Many aerospace components require a uniform, highly refined microstructure that translates into a high-performance part. Material experts use deformation modeling to develop billet conversion procedures that maintain thermo-mechanical conditions conducive to creating refined structures in the billet, center to surface.

|

|

|

| Figure 1. Strain profile during billet conversion in a radial press. | Figure 2. Strain profile of billet cross-section during conversion in a radial press |

In another example, the automotive industry often aims to improve tensile and torsion properties in components such as fasteners. Deformation modeling supports the manufacturing process by developing a cold drawing procedure to increase the strength of high alloyed bars. At the same time, modeling can optimize existing drawing procedures by selecting the ideal tool geometry and number of drawing passes, with the objective of minimizing processing time and increasing material yield.

To develop and optimize procedures for processes like forging, rolling, and drawing of specialty alloys with industry-leading performance, deformation modeling via Finite Element Analysis is an indispensable tool for our R&D team.

If you have any questions regarding the deformation modeling process or our specialty alloys, our expert team would be happy to assist you.