Etching 316/316L to Reveal Microstructure

Market Insights

Written by: A. Fraser

Etching 316/316L: How to stain stainless steel

Carpenter Technology’s 316/316L is an austenitic stainless steel with excellent hot workability, weldability, toughness, and pitting corrosion resistance due to its high molybdenum content and austenitic microstructure. These properties have made 316/316L a workhorse alloy in many industries, ranging from semiconductors to aerospace to oil and gas.

Because 316/316L is used across industries for a wide range of applications, its properties and microstructural features must be well understood to ensure correct processing for specific desired applications. These applications can include, but are not limited to, excellent sour service corrosion resistance for oil and gas drilling, excellent workability and toughness for aerospace, and superior elevated temperature corrosion resistance for semiconductor fluid-transfer systems.

Understanding the microstructure is critical to determining and confirming properties after processing, but it can be difficult to acid etch 316/316L to reveal the microstructure: The high chromium and molybdenum contents result in 316’s signature corrosion resistant properties. However, certain etchants and techniques can be used to study the microstructure, such as swab, electrolytic, and tint etchants designed specifically for stainless steels.

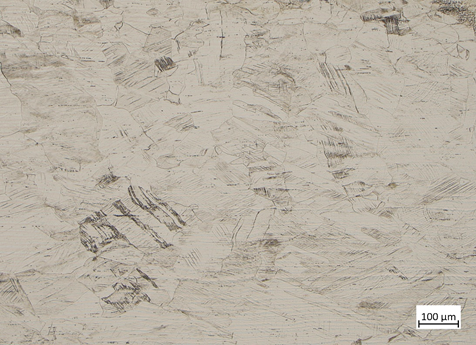

Swab etchants, such as Ralph’s or Waterless Kallings, can reveal an overall microstructure with austenitic grain boundaries, twin boundaries, and carbides visible. These swab etchants are useful for determining if a processing method resulted in the proper microstructure, such as adequate cold work for strengthening or precipitated carbides that may suggest sensitization.

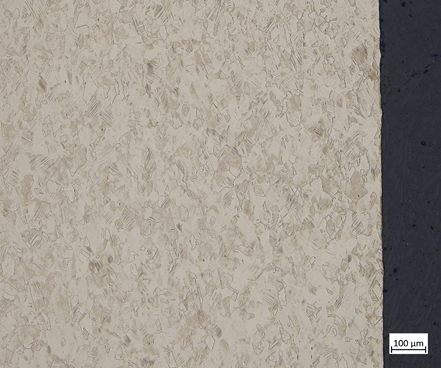

For precise measurement of grain size, electrolytic 10% oxalic acid clearly defines outer grain boundaries for image analysis and determines relative strength via Hall-Petch relationships.

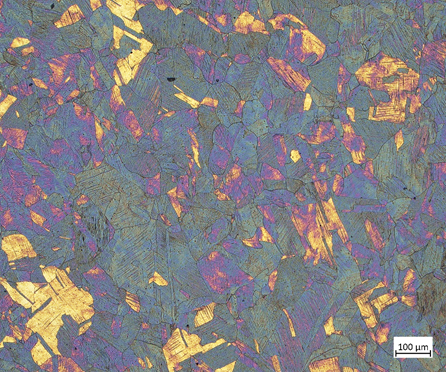

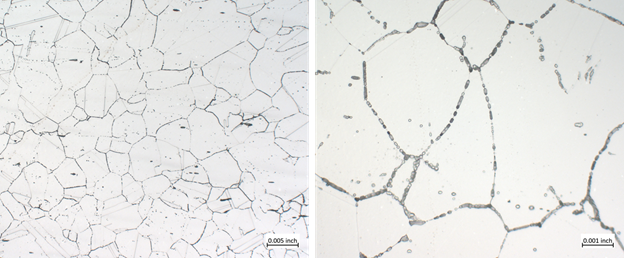

Tint etchants, such as Beraha’s immersion etchants, are ideal for identifying microstructural phases — brightly coloring austenite while leaving secondary phases unetched, allowing for easy phase fraction quantification. This type of tint etching is critical for evaluating material to be used in elevated temperature applications, as a sensitized microstructure, with deleterious carbide precipitation, can result in premature failure by intergranular corrosion.

Overall, understanding the microstructure is critical for determining the properties resultant of processing steps to ensure peak performance, none of which would be possible without suitable etching methods to reveal and confirm the microstructure of 316/316L.

Cold drawn 316L swab etched with Ralph’s reagent for 10 seconds at room temperature.

Strain hardened cold finished 316L electrolytically etched with oxalic acid at 6 V for 45 seconds at room temperature.

Cold drawn 316L tint etched with Beraha’s for austenitic stainless steels, submerged at room temperature for 10 seconds.

Sensitized 316 etched with 10% oxalic acid at 1 6 V for 90 seconds at room temperature, revealing carbides along grain boundaries.

Get in touch with the experts at Carpenter Technology to ask any questions about your unique application!