Improving Patient Outcomes with Small-Diameter Alloys

Market Insights

Author: Carpenter Technology

Improving Patient Outcomes with Small-Diameter Alloys

As surgical procedure technologies advance and robotic-assisted operations become more intricate, the need for materials that enable the smallest incision site are essential for patient satisfaction. Carpenter Technology provides smaller diameter titanium- and cobalt-based materials to help medical device producers meet this need, as well as increase efficiency by eliminating manufacturing steps and reducing scrap.

With stringent roundness, straightness, and finish requirements, small-diameter titanium delivers unprecedented dimensional consistency from end-to-end, bar-to-bar, and lot-to-lot.

ULTRABAR

Titanium ULTRABAR provides an in-stock solution for the exceptional dimensional accuracy high-precision medical devices require. In addition to meeting tight tolerances, using ULTRABAR can improve production and productivity up to 25%.

Ti 6Al-4V ELI

Ti 6Al-4V has excellent biocompatibility, good fatigue strength, and low modulus, and the ELI grade adds superior damage tolerance (fracture toughness, fatigue crack growth rate) and better mechanical properties even at cryogenic temperatures.

CP Ti Grade 1

Ti CP Grade 1 has the lowest strength and best ductility of the four primary ASTM grades due to its higher level of purity. Commercially pure titanium grades have high corrosion resistance, excellent biocompatibility and good formability.

CP Ti Grade 4

With the highest allowable oxygen and iron contents, Ti CP Grade 4 is the strongest grade of commercially pure titanium, with good ductility, moderate formability, and superior corrosion fatigue resistance in salt solutions.

Exotic Titanium Alloys

Exotic titanium alloys such as Ti6Al7Nb and Ti15Mo are typically used in orthopedic applications that demand higher mechanical properties than those achieved by conventional Ti alloys and where vanadium toxicity may be a concern.

Cobalt-based alloys provide exceptional wear and corrosion resistance, ultra-high tensile strength, and superior ductility and toughness.

BioDur® CCM

BioDur® CCM is a non-magnetic cobalt-chromium-molybdenum alloy with high strength and corrosion and wear resistance. A higher strength, wrought version of ASTM F75 cast alloy, BioDur® CCM meets ASTM F799, ASTM F1537, ISO 5832-4, and ISO 5832-12 requirements.

BioDur® L-605

BioDur® L-605 is a non-magnetic, chromium-nickel-tungsten-cobalt alloy with good oxidation, corrosion resistance, and ductility, as well as high strength properties at elevated temperatures. BioDur® L-605 is used in orthopedic cables, bone drill bits, and cardiology applications.

MP35N®

A non-magnetic, nickel-cobalt-chromium-molybdenum alloy with a unique combination of ultra-high tensile strength (up to 300 ksi [2068 MPa]), good ductility and toughness, and excellent corrosion resistance.

CONICHROME®

Conichrome is a non-magnetic, austenitic nickel-cobalt-chromium-molybdenum alloy with a unique combination of extremely high strength, ductility, excellent corrosion resistance, and high fatigue strength.

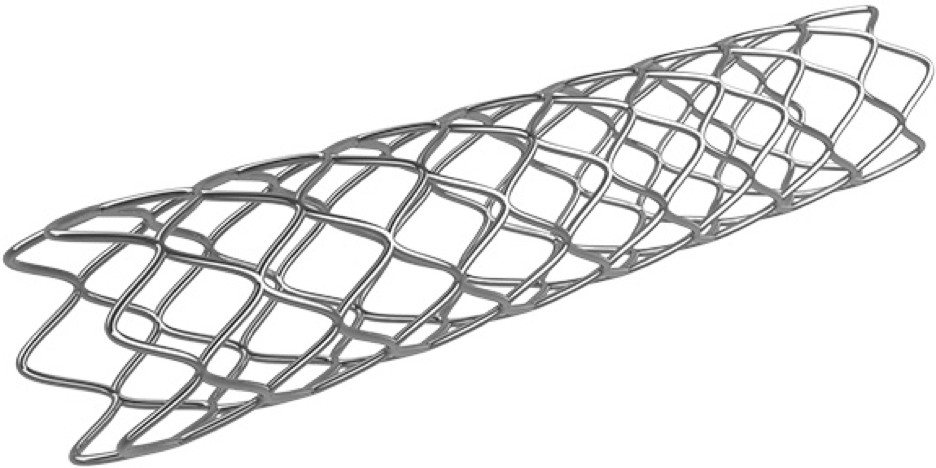

Whether reducing strut thickness and stent size to improve clinical performance or ensuring adequate strength for fine intravenous blades, Carpenter Technology’s small-diameter alloys deliver industry-leading performance — resulting in less invasive procedures with faster patient recoveries.