Improving Tomorrow's Infrastructure: Extending the Life of Concrete Structures with Solid Stainless Steel Reinforcing Bar

White Papers

Forward

In the wake of the I-35W Bridge collapse in Minneapolis, this paper is intended to heighten the awareness of the use of solid stainless steel reinforcing bar as a high-strength, corrosion-resistant alternative rebar product.

It is not meant to imply that the use of solid stainless steel rebar would have prevented this catastrophe. However, in light of the need to rebuild America's infrastructure, attention should be focused on the FHWA slogan of "Bridges for Life." Stainless steel reinforcing bar has clearly demonstrated its 100+ year life expectancy.

Abstract

Stainless steel reinforcing has been used in numerous structures throughout North America, including the Progreso Port Authority Bridge, Yucatan, Mexico, in 1937; the Haynes Inlet Slough Bridge, North Bend, OR, USA, in 2002; the Belt Parkway Bridge over the Ocean Parkway, Brooklyn, NY, USA, in 2004; and Woodrow Wilson Memorial Bridge on the Capitol Beltway, Washington, DC, USA in 2006.

Recent advances in concrete technology have provided structural designers with materials which can easily last more than 100 years, and the life of many concrete structures today is limited by the reinforcing. Improvements in the life of the reinforcing can translate directly into extended life of the structure.

Current projections by several transportation agencies show that the use of solid stainless steel reinforcing bar in bridge decks will more than double the life of the bridge deck.

While solid stainless steel reinforcing bar can increase the cost of the bridge deck by as much as 12% (compared to carbon steel reinforcing), the economic value of the longer life outweighs the initial higher cost. In most cases, the additional cost of solid stainless steel reinforcing bar represents less than 1.5% of the total cost of the structure.

Most concrete structures are designed with minimum concrete cover over the reinforcing bar, which is required to protect the reinforcing bar from corrosion. Where the reinforcing bar is completely resistant to corrosion, the cover can be reduced, saving costs of concrete and reducing the total weight of the structure.

In some structures, design savings made possible by the use of solid stainless steel reinforcing bar will offset as much as 100% of the initial cost increase from using the stainless reinforcing.

Introduction

Corrosion of carbon steel reinforcing bar has been a serious issue for highway agencies around the world for many years. In the United States, these problems appeared in southern coastal states as long as 75 years ago, and appeared in many northern states after the use of deicing salts became common about 50 years ago.

It would have been impossible in those early years of bridge design and construction for bridge and civil engineers to have foreseen the number of vehicles, and the huge loads that are being transported on these bridges today. In addition to the load concerns, deterioration due to the chloride salt content, either from the deicing salts employed or the salt spray in coastal regions, has severely impacted our bridge and roadway infrastructure.

For the last 35 or 40 years, rebar corrosion has been one of the most important issues facing bridge engineers. Upon entering the 21st century, engineers are now being confronted with an enormous number of deteriorating bridges, and new solutions are being evaluated daily to address these rising concerns.

The Federal Highway Administration (FHWA) along with many of the various state Departments of Transportation (DOT’s) began experimenting with methods to extend the life of concrete carbon steel reinforcing bar around 1970 as a result of these corrosion issues.

The FHWA has also been tasked with the problem of seismic retrofit, due in part to the seismic activity that can occur in various parts of the United States. Therefore, high strength and excellent ductility are paramount in preserving structural integrity, in addition to corrosion resistance.

Other FHWA projects include innovative bridge research and construction and value pricing projects based on full life cycle projections. Any or all the above mentioned projects may require a re-evaluation of the types of reinforcing materials currently being used.

Materials Employed for Reinforcing Bar Corrosion

One of the first methods developed is still the most common: coating carbon steel with an epoxy coating. The epoxy coating is intended to protect the carbon steel from moisture and from salts, and to electrically isolate a rebar mat from other nearby mats that may be at different potentials.

Early bridge decks constructed with epoxy-coated reinforcement bar (ECR) did not exhibit the desired long life. Analysis of early failures showed that poor adherence, or the poor quality of the epoxy coating, allowed corrosive salts to penetrate.

The concrete mixtures of that time had fairly high permeability, and the epoxy coatings provided only 5 to 10 years of additional life.

Subsequent testing showed that a principal cause of corrosion is the different potentials between the top and bottom mats in the deck. Many states began to use ECR in both the top and bottom mats for this reason (McDonald, et.al., 1998, and Samples, et.al., 1999).

However, the presence of uncoated composite shear studs in many bridge decks will provide an anode to initiate corrosion at defects in the top ECR mat. For this reason, the benefits of ECR bottom mats are limited.

The Concrete Reinforcing Steel Institute established a producer certification program for ECR, and the life of bridge decks using ECR is now in the range of 35 to 50 years in northern states where deicing salts are used (Humphreys, 2004).

The principal advantage of ECR is to provide longer life than that of uncoated carbon steel. Disadvantages include poorer bond with cement paste, fragility of the coating, adherence of the coating, and the limited life of the coating.

While CRSI’s certification program has substantially improved the initial quality of epoxy coatings, some studies have shown that damage to coatings during handling and concrete placement can be ten times the defects from the coating process itself (Samples, et.al., 1999).

High Performance Concrete (HPC)

Many agencies around the world have developed varieties of “high performance concrete” (HPC) in the last 15 years. Most of these mixes use substantially lower amounts of Portland cement than previous mixes, while adding fly ash, ground granulated blast furnace slag, and/or silica fume in various proportions.

These mixes show a reduced heat of hydration and a slower strength gain than many of the older mixes. They generally tend to have less shrinkage, less microcracking, and a much lower permeability than the more "conventional" mixes.

Many tests have shown that corrosion rates in bridge decks are related to the amount of cracking (Smith, et.al., 1996, & Fanous, et.al., 2000). HPC bridge decks are more durable than those constructed with older mixes, and many agencies believe they can consistently achieve 50 years life. Disadvantages are the slower curing times and, in general, the higher initial costs.

Galvanized Rebar

Many agencies began using galvanized carbon steel reinforcing bar more than 30 years ago. The galvanizing on carbon steel rebar has two functions: it protects the steel from corrosive chemicals, and it provides a sacrificial anode so that the steel itself will not corrode until the zinc coating is exhausted.

Some agencies have had good results with galvanized reinforcing bar, but the overall record of galvanized reinforcing bar is similar to ECR (Burke, 1994, & McDonald, et.al. 1998).

An HPC deck with galvanized reinforcing bar is generally estimated to have a life of 35 to 50 years. The advantages of galvanizing include a better bond to the cement (compared to ECR), and a less fragile coating.

Disadvantages include more price volatility, limited life of the coating, and the fact that galvanized rebar cannot be used in a placement with uncoated steel (because the coating will sacrifice itself to protect the uncoated steel nearby).

"Zn-ECR" Coatings

A U.S. producer has recently introduced reinforcing bar that is spray-coated with molten zinc and then epoxy-coated. Although it would appear that this product would have significantly longer life than ECR or uncoated galvanized rebar, further tests are needed.

Some preliminary tests have shown that the life of bridge decks constructed with this product will be longer than any product except stainless steel (Clemena, et.al. 2004).

However, the tests were not done with uncoated steel in the same placement. Since many actual bridge decks have uncoated shear studs, defects in the epoxy coating could create a site for accelerated corrosion.

This product would appear to have all the same limitations as ECR or galvanized rebar, such as poor bond, fragile coating, variations in coating thickness, etc.

Microcomposite Multistructural Formable (MMFX 2) Steel

This proprietary alloy is a low-carbon, 9% chromium alloy with unusually high tensile mechanical properties. Tests have shown that it provides significantly longer life than uncoated carbon steel reinforcing bar, and will probably provide longer life than ECR or galvanized steel (Clemena, et.al. 2004).

Some states now accept this material as a substitute for ECR, and some have discontinued the use of ECR entirely in favor of MMFX 2 or other materials with longer life.

While data is incomplete, it appears that an HPC deck, in conjunction with the use of MMFX 2 reinforcing bar, will have a life in the range of 30 to 50 years. Advantages of MMFX 2 include a good bond to the cement paste (compared to ECR), no problems with handling a fragile coating, and a higher yield at 0.2% deformation. Disadvantages include a sole source, poor ductility, and higher initial costs than ECR or galvanizing.

Fiber Reinforced Plastic (FRP) Rebar

This is the most recently developed material. It has been used in a few experimental structures. While the material itself will never corrode, it does have a limited life span. FRP does lose strength with age, and most experts in this field estimate a life of 65 to 90 years in service conditions before the loss of strength is unacceptable (GangaRao, 2007).

The principal problems with FRP reinforcing bar are high initial cost, low elastic modulus (generally requiring FRP to be used at least one size larger in deck designs), impossibility of bending (requiring prefabricated bends spliced to straight bars), and poorer bond with cement paste (comparable to ECR).

Another unanswered question with FRP is the value of thermal conductivity. Most designers have assumed that reinforcing bar serves several purposes: structural strength, crack control, and equalizing temperature (to reduce thermal stress).

FRP reinforcing bar has much lower thermal conductivity than any metal and will not equalize thermal stress as well as metal reinforcing. The authors have found no research on the probability of cracking from thermal stresses when non-conducting reinforcing bar is used.

Stainless Steel Clad Rebar

Two companies, one in the United Kingdom and one in the United States, have produced carbon steel rebar with a stainless steel cladding in recent years. This material has the potential of providing comparable life to solid stainless steel at lower cost.

Tests have shown that the only deterioration that occurs in this material is at the cut ends (Clemena, et.al, 2004), which must be capped to avoid corrosion of the carbon steel base.

However, its principal disadvantage is its limited availability. The only U.S. plant is not currently in production, and the U.K.-produced material may not be used on federally funded highway projects in the United States. Since the clad material is not readily available at this time, it is not practical for designers to specify it, and it will not be considered further here.

Solid Stainless Steel Rebar

Solid stainless steel reinforcing bar has been used successfully in very corrosive environments for more than 70 years. In 1937, the Progreso Port Authority, in the Port of Progreso, Yucatan, Mexico, constructed a bridge using stainless reinforcing rebar, AISI Type 304, due to the aggressive chloride environment of the saltwater where this bridge was built.

Almost 70 years later, this bridge is still standing and being used daily. According to the local authorities, this bridge has not had to undergo any type of major repair work throughout the life of this structure. A sister bridge, built to offset the heavy traffic flow in this area, was constructed in the 1960's using standard carbon steel rebar.

That bridge has been out of service for many years because the deck and foundation have almost completely disintegrated, due to a complete loss of the carbon steel reinforcing bar.

Tests by the FHWA and various states show that solid stainless steel reinforcing bar will last at least 100 years in typical northern state conditions (McDonald, et.al., 1998). The most commonly used alloys today are Type 316LN and Type 2205, which have significantly better corrosion resistance than Type 304.

Even though uncoated solid stainless steel rebar is exposed to potential differences between mats, the corrosion threshold is an order of magnitude higher than for carbon steel. Some tests with a stainless steel top mat and an uncoated carbon steel bottom mat showed that the top mat actually became slightly anodic, and the bottom mat corroded while the top mat was undamaged.

The obvious advantages of solid stainless steel reinforcing bar are extremely long life, excellent corrosion resistance and high strength with good ductility, good bond to the cement, no fragile coating, and no need of end caps. The disadvantage is the expense of the higher initial cost. Typically, solid stainless steel costs 2.5 to 4.0 times the cost of carbon steel.

However, new design life requirements, such as 100+ years, demand that bridge engineers evaluate both the overall construction costs and the total life cycle costs, as they decide what materials will give them their best option.

With maintenance and replacement costs measured in billions of dollars, due to the corrosion of carbon steel reinforcing bar in the United States, the total life cycle cost of bridge and highway structures should far outweigh the initial cost of materials.

Recently, Talley Metals, a Carpenter Technology Corporation company, introduced a new, lower-cost stainless steel alloy, CarTech EnduraMet® 32 stainless, which has been used for concrete reinforcing bar. Corrosion resistance and most structural properties are similar to AISI 316LN or 2205.

However, the low nickel and its metallurgically balanced alloy content reduces its cost dramatically. Typical purchase costs for EnduraMet 32 stainless are from 1.5 to 2.0 times the cost of carbon steel, or about one half the cost of AISI 316LN or CarTech EnduraMet 2205 stainless.

The standard specification that covers stainless steel reinforcing bar is ASTM A-955, and EnduraMet 32 stainless meets all the strength requirements of the various grade levels and far exceeds the ductility requirements, making it easy to form while maintaining its superior strength.

Corrosion macrocell testing, which measures the corrosion rate of steel rebar, including stainless, in a simulated concrete pore solution, has demonstrated that EnduraMet 32 stainless far exceeds the proposed ASTM requirement of 0.25µm/year average by attaining 0.015µm/year average in a 15 week test period.

The FHWA’s slogan, “Get in, Get out, and Stay out,” which is commonly used in describing the need to minimize any disruptions to traffic flow, is intended to improve the public’s perception regarding the rehabilitation of road and bridge structures.

The use of solid stainless reinforcing bar, in critical bridge decks and components will significantly improve the life of these structures, thus meeting the FHWA’s intention.

Comparison of Alternatives

Bridge designers have the choice of various types of reinforcing bar as outlined above. The choice of material will depend on life span, reliability, and economic issues such as initial capital cost and total life cycle cost.

New bridges in most states today are designed for a 75 year life span, and some major structures are designed for a century or more. In the past, most bridge agencies have accepted the fact that a 75-year bridge will require at least one major rehabilitation during that period.

However, especially in urban areas, major rehabilitations have proven to be very expensive and have caused substantial disruptions to normal traffic flow. Bridge owners have been looking for more durable materials, and some of the materials described above can provide substantially longer life at relatively low cost.

FRP reinforcing and the various solid stainless steel options all can provide bridge deck with a life span of 75 years or more. The “Zn-ECR” material may achieve this life span, but more testing will be needed. However, when a designer considers other structural properties such as bond to the cement paste, the FRP and Zn-ECR materials are no better than “conventional” ECR.

The solid stainless steel reinforcing bar options alone have the durability to last more than 75 years (and most could last more than 100 years), and all can deliver optimum structural properties.

As noted above, the stainless steel options may have the highest costs. Bridge designers cannot arbitrarily select a more expensive material just because it will last longer. Most agencies use life-cycle cost comparisons when selecting different materials for bridges (and highways), and this practice is encouraged by FHWA.

The section below is intended to illustrate the economic comparisons between selected rebar options and to give guidance to bridge designers when they are selecting materials for new bridges and for major bridge or roadway rehabilitations.

Economic Comparisons

Most decisions to use materials with more or less durability are based on cost. Since the projected life of concrete bridge elements is always greater than 25 years, a simple cost comparison cannot be used.

The FHWA and most state agencies use a life-cycle cost comparison, using an estimated discount rate based on interest minus inflation. Historically, this rate has always been near 4%, and that figure will be used throughout this paper.

As noted above, a well constructed HPC deck with ECR in top and bottom mats can reasonably be expected to last 35 to 50 years in most northern states. An identical deck with solid stainless reinforcing could last as much as 120 years, but no one has projected the life of the concrete itself that far.

Current costs for both carbon steel and stainless steel are rising rapidly. The best available figures today are that the purchase cost of stainless steel (AISI 316 or 2205) will be about 2.5 to 4.0 times the purchase cost of carbon steel.

Placement costs are virtually identical. In the New York City area, rebar placement cost is generally equal to the purchase cost of the carbon steel. Thus, in the NYC area, in place costs for solid stainless steel are 1.75 to 2.25 times the cost for ECR.

The price of deck reinforcing (ECR) generally represents about 10% to 14% of the cost of the entire bridge deck. Assuming the average of 12% for ECR, solid stainless steel would represent an increase in cost of 9% to 15% of the entire deck, compared to ECR.

Assume that a bridge deck constructed with ECR will last 40 years and will then be replaced at current costs. The present worth of the 40-year replacement is equal to 20.83% of the cost of the deck today. However, the cost of related construction items such as demolition, barriers, railing, joints, and maintenance and protection of traffic must be added to the deck costs.

If the related elements add about 25% to the deck costs, the present worth of the 40-year replacement is 26.04% of the cost of today’s construction. This compares favorably with the 9% to 15% increase in costs to use solid stainless steel instead of ECR.

Obviously, in highly congested areas such as central city arterials, maintenance and protection of traffic costs are unusually high. The high cost of detours and the high cost of deck repairs that become necessary near the end of the life of the deck make the comparison even more favorable to the stainless steel reinforcing.

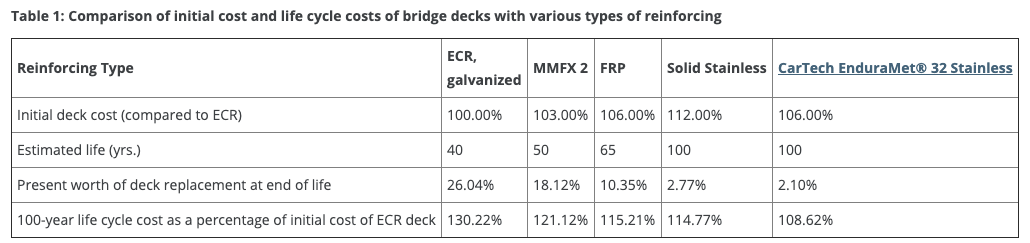

The following table illustrates the relative cost of new bridge decks constructed with ECR (or galvanized rebar), MMFX 2 material, FRP, Solid Stainless, and EnduraMet 32 stainless. While the longer-lived options (FRP and stainless) have a higher initial cost, the life cycle costs of these decks are actually lower than the "conventional" ECR deck.

Design Assumptions:

- Present worth of deck replacement and 100-year life cycle costs assume 25% for related costs of replacement (M&PT, demolition, etc.).

- 100-year life cycle cost assumes replacement with identical deck design at end of each life span. Remaining salvage value at 100 years is deducted.

- FRP values assume equivalent linear quantities, with all bars 1 size larger than steel bars.

- "Solid stainless" assumes AISI 316LN or 2205.

Design Improvements Available with Non-Corrosive Reinforcing

All the comparisons above assume that all decks are designed identically, using the Standard Specifications for Highway Bridges or “empirical” methods. However, the use of non-corroding reinforcing will allow design savings in other areas.

Reduced Deck Thickness

Most bridge owners require a minimum cover over the top mat of reinforcing between 50 mm (2 in.) and 75 mm (3 in.). The common standard in many U.S. states is 62 mm (2.5 in.) while New York requires 75 mm (3 in.). New York also allows a designer to reduce the top mat cover by 25 mm (1 in.) if non-corroding reinforcing is used in the top mat.

Since NYSDOT’s “standard” bridge deck with ECR is 240 mm (9.5 in.) thick, the use of non-corroding reinforcing allows a reduction in deck concrete volume of 10.52%, with a corresponding reduction in dead load of the deck.

Concrete material and placing costs represent about 9% to 10% of the cost of a bridge deck. Thus, the 10.42% reduction in thickness will reduce the initial cost of the deck by approximately 1%. Since the cover over the top steel is not included in the flexural design of the deck, there is no loss in structural capacity from the reduced slab thickness.

Reduction in dead weight of the deck will reduce the total dead load of the structure. For a typical multi-span continuous steel plate girder structure with spans in the range of 60 m (200 ft.), the deck dead load represents about 65% of the total dead load, and about 40% to 45% of the total dead plus live load.

The demand on the girders will thus be reduced by about 4%. For the more common continuous structures, this analysis assumes that there will be very little savings of structural steel in the positive moment areas, because the reduction in deck thickness will effectively reduce the area of the composite girder flange. However, since composite action is not assumed in negative moment areas, a savings comparable to the reduction in demand will be achieved in those areas.

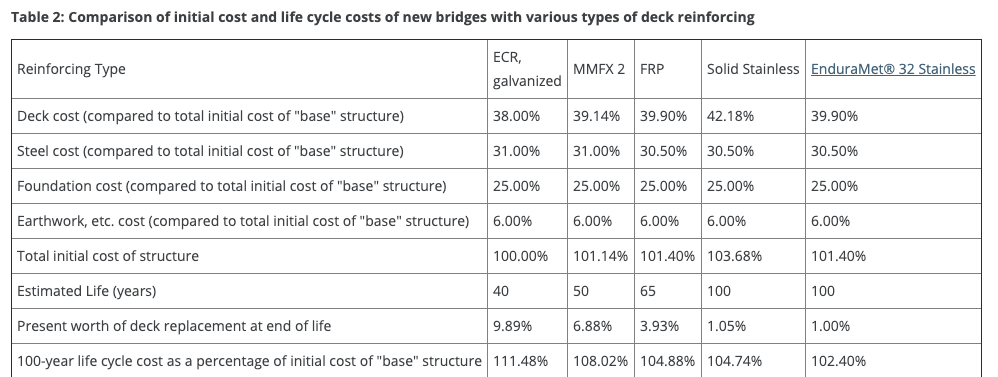

The following analysis assumes a 4.45% reduction in demand on the girders in negative moment areas only, and an equivalent reduction in structural steel cost in those areas.

Design assumptions:

- DL of structural steel is 50% of DL of concrete (std. deck).

- Deck cost is 38% of the cost of the “base” structure.

- Steel cost is 31% of the cost of the “base” structure.

- Foundation is 25% of the cost of the “base” structure.

- Earthwork and misc. is 6% of the cost of the “base” structure.

- DL of concrete reduced 10.5% by reduction of deck thickness.

- Cost of deck is reduced 1.0% by reduced thickness.

- Total DL is reduced by 7.0%.

- Total DL + LL + I is reduced by 4.45%.

- Demand on girders in negative moment areas is reduced by 4.45%.

- Flange thickness of girders in negative moment areas is reduced by 4.45%.

- Self weight of steel in negative moment areas is reduced by 4.0%.

- Negative moment areas represent 40% of entire structure.

- Total weight and cost of structural steel is reduced by 1.6%.

- No reduction in foundation costs from reduced DL.

- Other assumptions same as Table 1.

Table 2 shows that a bridge using EnduraMet 32 stainless in the deck will have an initial cost only 1.4% higher than the same bridge using ECR, when the savings in structural steel are computed.

Higher savings in structural steel could actually reduce the higher initial cost for EnduraMet 32 stainless, but it is unlikely that the net initial cost difference could be reduced to zero, unless other savings can be found.

Reduced Foundation Costs

Table 2 assumes that there are no improvements in foundation design available from the reduction in dead load. In many cases, that is a valid assumption. However, for structures in poor soils, especially where high foundations are used, the reduction total dead load plus live load will provide savings in foundation design, especially where the foundation is governed by seismic loads.

A reduction in dead load of a superstructure supported by a tall pier can substantially reduce the seismic demand on that pier. This reduction can reduce the size of the pier column and can also reduce the size and cost of the footing or pile cap. The number of piles can sometimes be reduced.

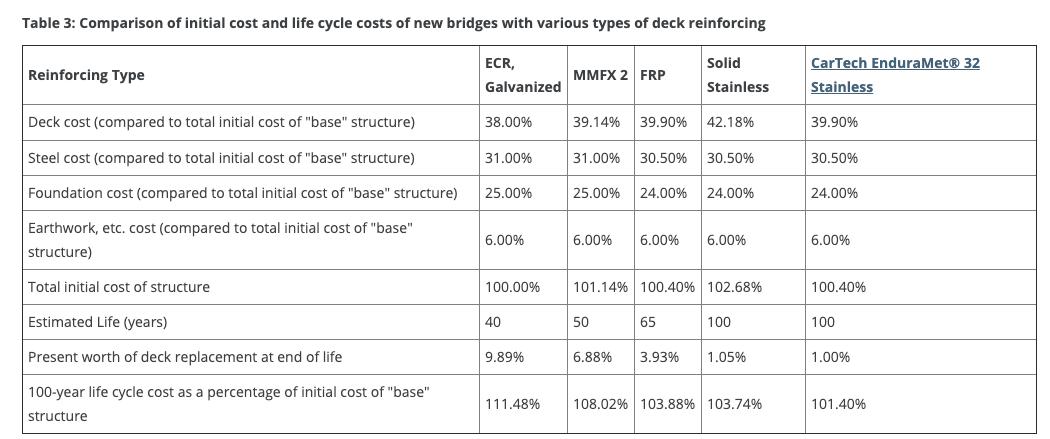

Table 3 assumes that the 4.0% savings in superstructure cost is achieved in foundation cost also. This is obviously an arbitrary assumption: foundation savings in many structures will be very small, while a structure with tall column piers in very poor soil may achieve savings in the range of 5% to 8%. When designing structures in these conditions, designers should consider various methods of reducing weight, including non-corrosive reinforcing, lightweight concrete, etc.

Design assumptions:

- Foundation cost reduced by 4.0% where DL is reduced by 7.0%.

- All other assumptions same as Tables 1 and 2.

Table 3 is identical to Table 2 except for the reduced foundation costs for the FRP, Solid Stainless, and CarTech EnduraMet 32 stainless options. For solid stainless steel (AISI 316 or 2205), a 15% reduction in foundation costs would actually reduce the total initial cost of a structure using solid stainless tell rebar below the “base” structure.

While this is unlikely, except possibly in extremely poor soil conditions, the reduction in superstructure dead load can provide substantial reduction in cost for the entire structure. For EnduraMet 32 stainless, a 7% reduction in foundation costs will reduce the total initial cost of the structure below the initial cost of the “base” structure using ECR in the deck. While this reduction in foundation cost will not be available on the average highway bridge, it could be achieved in some cases.

Use of stainless steel reinforcing in foundations

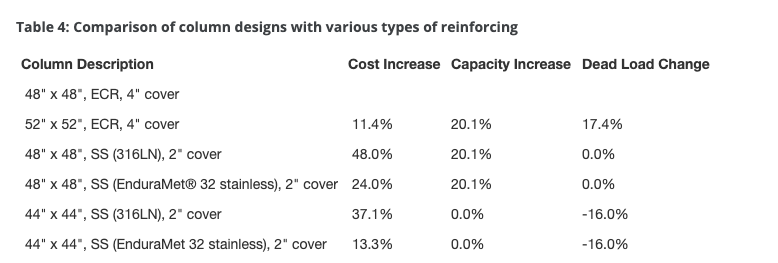

Stainless steel reinforcing is not commonly specified in bridge supports such as columns or stem piers, but designers may want to consider several options. Foundation structures vary so widely that precise comparisons can be difficult to quantify. The following discussion is based on a “common” bridge support column in a marine environment (footing or pile cap in sea water). The “sample” column is 48 inches square, contains 36 #11 vertical bars (10 per side), and uses #4 ties at 6” o.c. vertically. Cover is 4”, which is required by many agencies for structures in sea water.

If solid stainless steel reinforcing is used, the designer has the choice of reducing the cover to 2” or relocating the vertical bars closer to the original surface. Relocating the vertical bars closer to the surface will increase the capacity of the column without increasing weight or size.

Reducing the cover while maintaining the position of the bars will not affect the original capacity but will reduce the size and weight of the column. The following table illustrates the relative costs and benefits of these options:

Design assumptions:

- Cover is reduced by 2" using solid stainless rebar.

- A 1" decrease in the deck thickness occurs using solid stainless rebar.

- The life of the column may exceed 100 years.

- The DL is reduced by 16%.

- A corresponding decrease in the cost of the supporting foundation may occur.

- Column size, i.e. cross section, is reduced by 16%.

The table shows that a designer who needs to increase the capacity of the “basic” column can simply increase the size, with a cost increase of 11.4% and a dead load increase of 17.4%. The dead load increase will affect the cost of the supporting foundation, but this cannot be quantified here.

A designer who needs to increase the capacity of the basic column but cannot accept the increased dead load can accomplish that goal by specifying stainless steel reinforcing at reduced cover. The cost of the column could increase by 48% (316LN stainless) or by 24% (EnduraMet® 32 stainless) but with no other increase in costs. The life of the column can be expected to exceed 100 years.

If a designer wants to extend the life of a column but its capacity is adequate, the size can be reduced by using stainless steel reinforcing. The cost of the column will be increased by 37.1% (316LN) or 13.3% (CarTech EnduraMet 32), and the capacity will remain unchanged. The dead load will be reduced by 16%, and there may be a corresponding decrease in the cost of the supporting foundation.

Examples

The New York State Department of Transportation is presently designing two bridge rehabilitation projects using solid stainless steel reinforcing in the deck. Each bridge has some unusual circumstances. In each case, the additional cost of solid stainless steel (combined with lightweight concrete in one case) can be completely offset by resulting design efficiencies elsewhere in the project.

Alexander Hamilton Bridge

This steel riveted spandrel arch bridge carries I-95 across the Harlem River. Approach spans are steel multi-girder. The scope of the project is deck replacement, widening, steel rehabilitation, and seismic upgrades.

The increased dead load would have required substantial reinforcement of the existing riveted steel spandrel arch ribs and spandrel columns. The weight savings achieved by the use of stainless steel reinforcing have made most of this reinforcement unnecessary. Not only will the total cost of construction be reduced as a result of using stainless steel, but construction time will be reduced by approximately six months.

Undercliff Avenue Bridge

A related project is the Undercliff Avenue Bridge, which carries a local street over the eastern approach to the Alexander Hamilton Bridge. Because of constrained highway profiles, the replacement structure must span more than 100 feet with welded plate girders 32” deep. This uneconomic section will require girder spacing of less than 6 feet.

The use of stainless steel reinforcing has allowed a 1 inch savings in deck thickness to be applied to the girder depth. Adding 1 inch to the girder depth has enabled the designers to eliminate one of the girders in the original design, resulting in lower overall cost of the project.

Major Deegan Expressway Viaduct

This is a 72-span, steel riveted viaduct carrying I-87 over local streets near Yankee Stadium. The scope of work is deck replacement, widening, steel rehabilitation, and seismic upgrades.

The widening of the structure – required for highway geometry and for maintenance of traffic during construction – would have required 16 new pile-supported foundations. The use of stainless steel reinforcing and lightweight concrete in the new deck has made those foundations unnecessary and has also substantially reduced the cost of the seismic upgrades.

Conclusion

The use of carbon steel reinforcing bar has been common for more than 100 years. Recent advances in materials will provide superior durability and reduced life cycle costs compared to carbon steel, even when epoxy coated or galvanized. Some more modern materials, such as solid stainless steel reinforcing bar, will actually provide a reduced total cost of a new bridge structure in specific cases while providing longer life, at no additional cost.

The various relative costs and percentages given above are based on specific assumptions, which the authors believe are representative of typical bridge projects. These assumptions will obviously not be valid for all cases.

This paper is intended to illustrate that choosing the more expensive material does not always result in a more expensive project. The economic savings available from the use of better materials can frequently offset the higher initial cost of those materials, when one employs the use of full life cycle cost analysis.

The examples above are unusual, but they illustrate that the use of more expensive and longer-lasting materials may not actually increase the initial cost of a bridge project.

In all three cases, the increased cost of the stainless steel reinforcing will be completely offset by savings elsewhere. The longer life of the stainless reinforcing is essentially “free” to the owner and the taxpaying public.

Bridge designers should evaluate different reinforcing materials during the design of major rehabilitation projects, as well as any new bridge project. A project involving deck replacement and steel repair on a deteriorated bridge could use the design advantages of corrosion resistant reinforcing bar to reduce the cost of steel repairs.

The weight savings can substantially reduce the cost of a seismic upgrade for an older bridge that is being rehabilitated. The methodology used here can be used by designers to determine the economic value of various design options on many bridge projects.

References

Burke, D.F., 1994. Performance of Epoxy-Coated Rebar, Galvanized Rebar, and Plain Rebar with Calcium Nitrite in a Marine Environment, pub. Naval Facilities Engineering Service Center, reprinted by CRSI.

Clemena, G.G. & Yirmani, Y.P., 2004. Comparing the Chloride Resistances of Reinforcing Bars, Concrete International, Nov. 2004, pp. 39 – 49.

Cui, Fushuang & Krauss, P.D.; 2006. Corrosion Resistance of Alternative Reinforcing Bars: An Accelerated Test, Pub. By CRSI.

Darwin, D.; Browning, J.; Nguyen, T.V.; & Locke, C.; 2002. Mechanical and Corrosion Properties of a High-Strength, High Chromium Reinforcing Steel for Concrete, FHWA report SD2001-05-F.

Fanous, F.; Wu, H.; & Pape, J.; 2000. Impact of Deck Cracking on Durability, Iowa DOT Project TR-405,

GangaRao, H. 2007. Verbal communication at Polymer Composites Conference IV.

Hartt, W.; Lysogorski, D.; & Leroux, V.; 2004. Characterization of Corrosion Resistant Reinforcement by Accelerated Testing.

Humphreys, S.R.; 2004. Improving the Quality of Epoxy-Coated Steel Reinforcing Bars through CRSI’s Epoxy Coating Applicator Plant Certification Program, pub. CRSI.

Lee, S.-K. & Krauss, P.D.; 2004. Long-Term Performance of Epoxy-Coated Reinforcing Steel in Heavy Salt-Contaminated Concrete, Report No. FHWA-HRT-04-090.

McDonald, D. B.; Pfeifer, D. W.; & Sherman, M. R.; 1998. Corrosion Evaluation of Epoxy-Coated, Metallic-Clad and solid Metallic Reinforcing Bars in Concrete, Publication FHWA-RD-98-153.

Samples, L.M. & Ramirez, J.A.; 1999. Methods of Corrosion Protection and Durability of Concrete Bridge Decks Reinforced with Epoxy-coated Bars - Phase I, Report FHWA/IN/JTRP-98/15.

Smith, J.L. & Yirmani, Y.P.; 1996. Performance of Epoxy Coated Rebars in Bridge Decks, Publication FHWA-RD-96-092.

Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his/her own evaluation and are not intended as warranties, either express or implied, of fitness for these or other purposes.

***

R. E. Schnell

Talley Metals Technology, Inc., Hartsville, SC, USA

M. P. Bergmann, P.E.

New York State Department of Transportation, Long Island City, NY, USA

Presented at the 2007 New York City Bridge Engineering Conference August 28, 2007