Metallographic Etching for Waspaloy to Reveal Microstructure

Market Insights

Author: J. Schaefer

Etching Waspaloy: Selecting the right etchant

The ability to analyze an alloy’s microstructure is critical for design, improvement, and quality control. Waspaloy, an important aerospace grade found in high temperature engine parts, is no exception.

As a nickel-based superalloy, Waspaloy has excellent high temperature strength and corrosion resistance, specifically against oxidation. It is used up to 1200°F in rotating applications and up to 1600°F for less demanding applications. Waspaloy’s major strengthening mechanism is gamma prime, which is not visible by optical microscopy. Microscopic examination, however, is still important, as grain boundaries, carbides, and to some extent, twin boundaries hold a lot of answers to the properties of Waspaloy.

Waspaloy gets its superior strength from multiple mechanisms. These include the aforementioned gamma prime formation, as well as solid solution strengtheners and carbides. Gamma prime forms when nickel reacts with aluminum or titanium to precipitate Ni3Al and/or Ni3Ti. This phase causes strain in the lattice, and it gains strength at elevated temperatures, which results in the alloy’s superior high temperature strength. Solid solution strengtheners include molybdenum, cobalt, and chromium. These elements lie within the nickel matrix and also strain the lattice, resulting in increased strength.

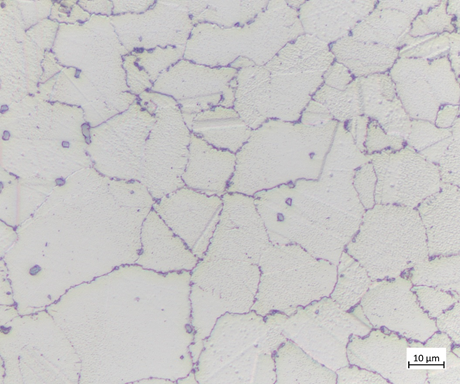

Carbide-forming elements include chromium and titanium. Chrome carbides are typically the smaller of the two and form at the grain boundaries. Titanium carbides are larger and present themselves in the matrix. Grain boundary carbides pin the grain boundaries and prevent the grains from growing at high temperatures. This is critical to the alloy’s high temperature performance. If the alloy is heated and the grains grow freely, it would result in a significant loss of strength. Both grain boundary and matrix carbides strengthen the alloy.

Attacking any alloy with the right etchant is the key step for microstructural analysis. Carbides and grain boundaries will be visible in an etched material. Ensuring a reasonable grain size and good dispersion of carbides is important to the material in achieving its properties. If there are no carbides present on the grain boundaries, the grains will grow more rapidly at high temperatures, resulting in a loss of strength. If a uniform distribution of interstitial carbides is not present, the alloy can also suffer in its strength.

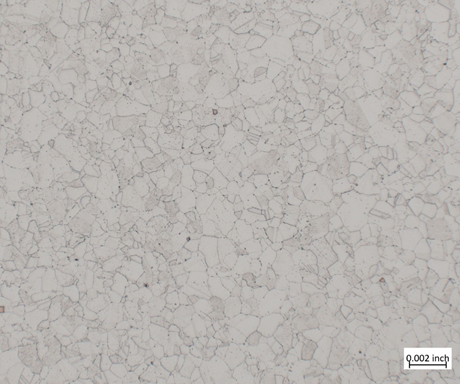

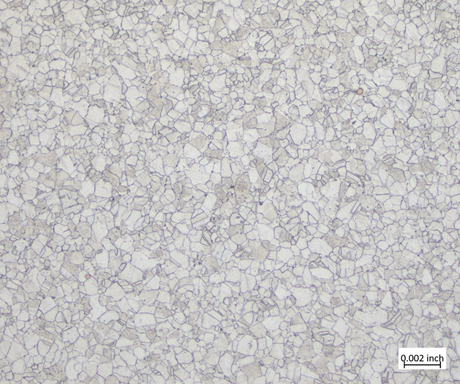

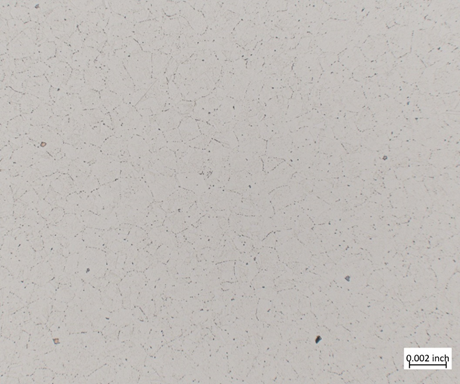

To properly etch and analyze Waspaloy, here is what you need to know: If you want to analyze grain boundary carbides, glyceregia is the answer. For a more shaded appearance and easy-to-pick-out twin boundaries, Lucas’s reagent is the go-to. In the interest of simplicity, Waterless Kalling’s will provide the easiest attack on grain boundaries and carbides for an easy-to-see microstructure. Any of these options will provide an etched microstructure for analysis.

Waspaloy etched with Lucas’s reagent.

Waspaloy etched with glyceregia.

Waspaloy etched with Waterless Kalling’s.

Grain boundary carbides.

Get in touch with the experts at Carpenter Technology to ask any questions about your unique application!