We're your best partner for building a better future.

CONTACT SONIC TESTING RESOLUTION

ERGONOMICS. EVERYWHERE.

GETTING OUT OF A SLIPPERY SITUATION

Our project started when our workload significantly increased. It takes six months for a new operator to become certified, which meant our existing staff would have to work much longer hours manually testing products. Concerns were raised by the operators, who were experiencing wrist and neck fatigue. Our collaborative solution addressed both ergonomic risks and production needs.

JASON BOLTON, UT LVL II OPERATOR

JASON BOLTON, UT LVL II OPERATOR

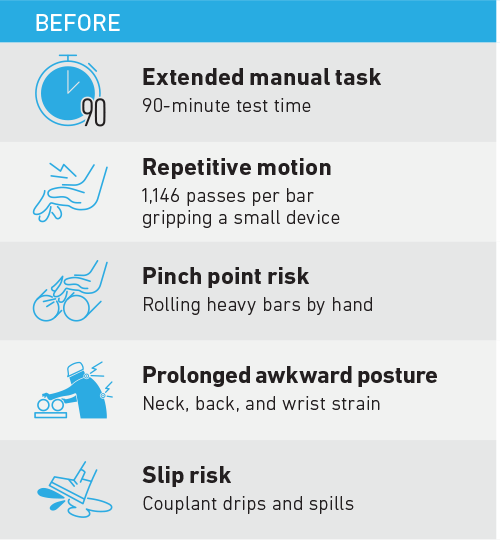

The problem

MANUAL TESTING

Non-destructive testing (NDT) operators at our Athens facility were manually testing drill collars, very large tubular pieces of solid steel used in industrial drilling operations. The operators would slather each 35-foot, 1.5-ton steel bar with a slippery couplant (similar to an ultrasound gel used for pregnancies) and then hand roll the bar 360 degrees end-to-end. They would do this once for contact ultrasonic testing (UT) and again for magnetic hot spot testing. This happened over and over, roughly 2,667 bars a year.

The ergonomic strain of this high-volume, manual testing was substantial and the operators knew there had to be a better way.

“Testing bars for defects manually required a lot of wrist motion and constantly looking down at the screen. I felt it mostly in my wrists and neck. As my hands got tired, I had to slow down to still get a good contact with the probe.”

The solution

INNOVATING AUTOMATION

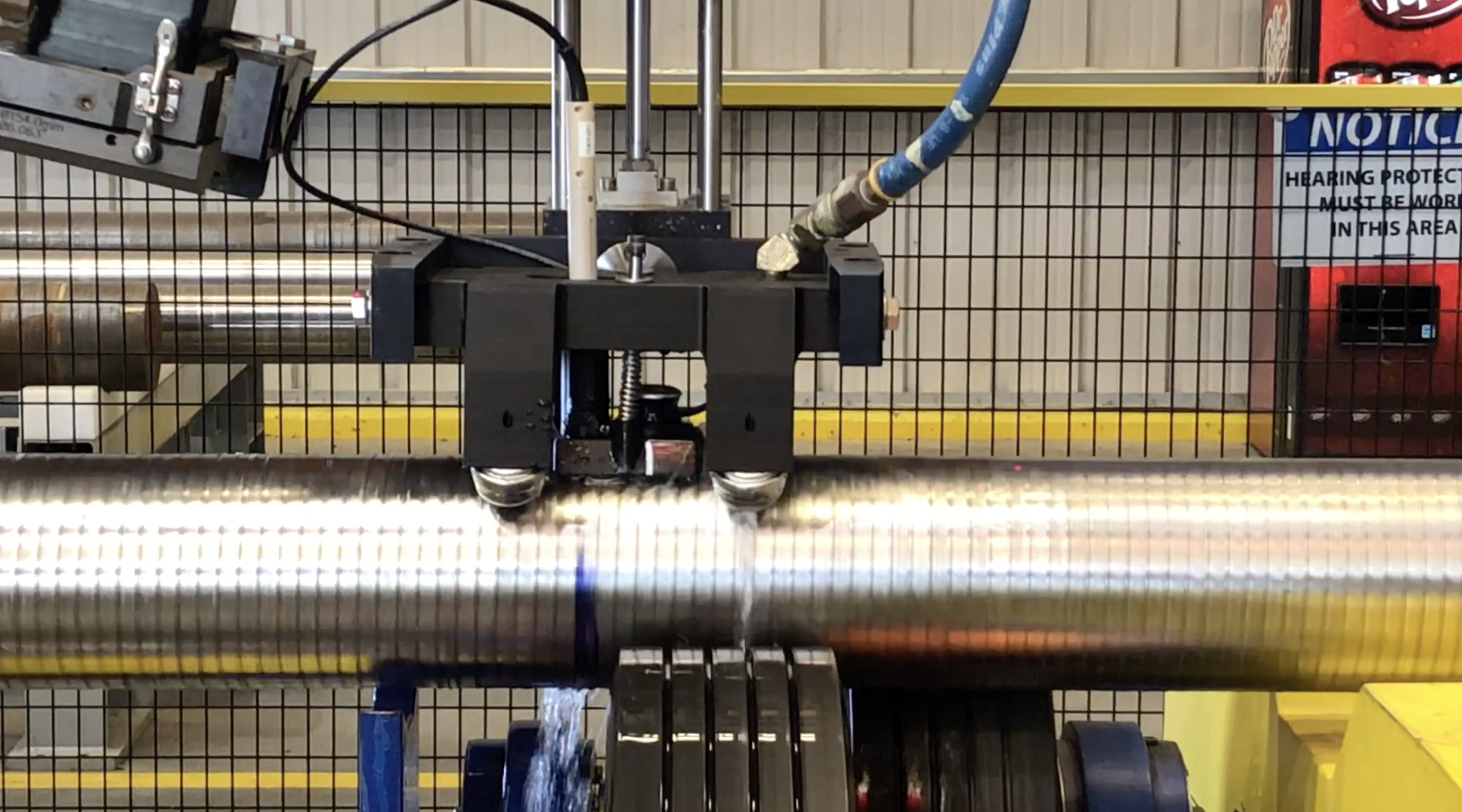

Working together with Carpenter Technology’s engineering and metallurgy groups, the NDT operators designed an innovative, automated solution to this problem. Using the company’s in-house, 3D printing capabilities, the joint team repurposed an unused rotating bar inspection system (RBIS) to perform both sets of tests.

After multiple, comprehensive collaboration sessions and five different rounds of prototypes, the new process was perfected utilizing just $200 in materials and with only the internal resources available.

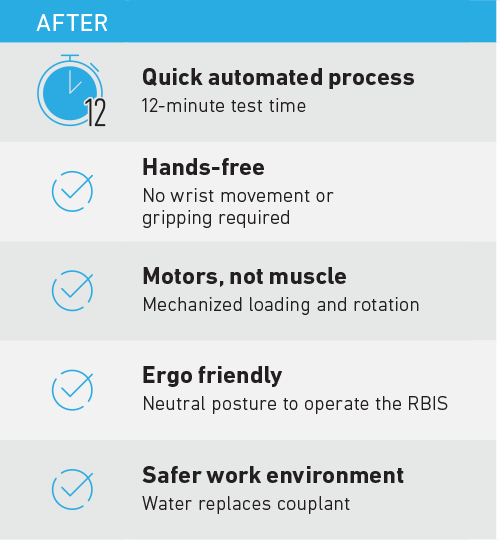

The solution realized multiple benefits:

- It replaced all of the group’s manual testing

- It utilized plain water instead of slippery couplant

- It provided the company with additional data in a strip chart record

“Now, the machine does the work. I monitor the equipment and make the final pass/fail decision from a computer screen. Not only did we eliminate the ergo hazards, we sped up production time and can keep up with the workload.”

—Jason Bolton, UT LVL II Operator

The Impact

FULL CIRCLE

UT and magnetic hot spot testing are now conducted on the retrofitted RBIS — automatically, hands-free, couplant-free, in a fraction of the time.

THE SOLUTION WAS AS ELEGANT AS IT WAS IMPACTFUL.

The process changed overnight.

- 3+ million fewer wrist movements every year

- Ergonomic risks eliminated: pinch points, bent posture, twisting and slipping

- 3,467 work hours saved annually, freeing the team to work and innovate in other areas

- $235,763 labor costs saved annually that are now invested in other projects

- 2.5 days faster lead times for customers

- Team safety protected