EU MDR Compliance In Stainless Steels For Medical Applications

Market Insights

EU MDR compliance in stainless steels for medical applications

The Center for Devices and Radiological Health (CDRH) estimates that about 15% of the general population is sensitive to cobalt and/or nickel. Exposure to metal ions released from the normal wear of medical implants can lead to adverse side effects, including hypersensitivity, implant loosening, and premature device failure, leading to life-threatening outcomes.

In 2017, the European Union implemented regulatory changes (EU MDR) to limit the cobalt content in medical devices without a definitive solution, creating a wide disconnect between device manufacturers and material suppliers. Commonly used stainless steel alloys such as 300 series, 400 series, Custom 455, and Custom 465 typically contain 0.5 to 0.40 wt% cobalt attributed to impurities during the melting process, making them non-compliant with new regulations.

Carpenter Technology has prioritized creating EU MDR-compliant, low-cobalt and nickel-free stainless steel alloys to reduce exposure and improve patient outcomes.

EU MDR and its impact

EU MDR defines comprehensive requirements for medical device manufacturers to achieve compliance and mandates CE marking. EU 2017/745 introduced regulatory changes, up-classifying cobalt as a carcinogen, mutagen, and reproductive toxin. All medical devices with more than 0.10 wt% cobalt now require warning labels.

Meeting EU MDR requirements

Carpenter Technology moved quickly to meet the new EU MDR requirements by developing low-cobalt stainless steel variants of our FDA-approved alloys:

-

Austenitic: 316L, BioDur® 108, BioDur® 316LS (316LVM), BioDur® 734

-

Ferritic: 430

-

Martensitic: 410, 416, 420, 440A/C, TrimRite

-

PH Stainless: Custom 455, Custom 465, Custom 470, Custom 630 (17-4)

These variants were produced by refining scrap streams and melt protocols. In addition to EU MDR compliance, the updated alloys provide improved mechanical and corrosion resistance properties.

Melting matters

Melt technology is a vital step in enhancing alloy and component performance:

-

Tight elemental raw material control through melting drives material advancements in traditional alloy families.

-

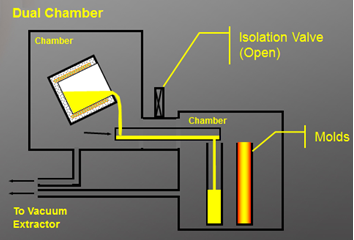

Vacuum melting and re-melting techniques like VIM / VAR / ESR create improved metallurgical properties.

-

Powder melting facilitates next-level strength, high hardener material additions, and additive manufacturing processes.

Carpenter Technology starts with raw elemental additions and owns the melting process from start to finish — we control the precise chemical composition of our alloys. This control makes our materials ideal for bone plates, screws, spinal fixation, hip and knee components, and other implants and medical devices.

Next-gen materials

Carpenter Technology alloys are engineered for EU MDR compliance and performance.

BioDur® 734 is a cobalt-free, nitrogen-strengthened, austenitic stainless steel with improved tensile strength, impact strength, fatigue strength, and corrosion resistance over standard BioDur® 316LS. Electro-slag remelting (ESR) ensures its microstructural integrity and cleanness.

BioDur® 108 is a nickel-free, cobalt-free, nitrogen-strengthened, premium-melted austenitic alloy that serves as an alternative to 316/316L in applications where nickel and cobalt are concerns. Cold work enhances mechanical properties, resulting in strength exceeding 200+ ksi.

Custom 465 stands out in high-strength, high-toughness, and corrosion-resistant applications, making it a workhorse in the medical industry. The alloy is available in ASTM A564-19a, Condition CW + Age —ready for aging treatment with impressive tensile strength potential.

Custom 470 offers similar exceptional performance to Custom 465 but is melted via powder technology and re-tuned chemistry, specifically tailored for the small diameter needle market. The alloy is an excellent option for tight control during gun drilling applications for tubular components.

A-21® is a new-to-world advanced martensitic stainless steel with high case hardness, high core toughness, and stainless properties. The low-cobalt alloy has versatile use-cases, including carburizing, nitriding, and quenching and tempering applications.

Carpenter Technology is committed to delivering cutting-edge materials that deliver superior performance and safety, ensure EU MDR compliance, and contribute to advancements in medical technology and patient care.

Learn from the experts

Carpenter Technology hosted an in-depth webinar about EU MDR-compliant stainless steels for medical applications in July. Tune in to hear more about these life-changing alloys from our Global Medical Applications Engineering Lead Gaurav Lalwani, PhD, and our Regional Field Metallurgist Ray DeFrain.