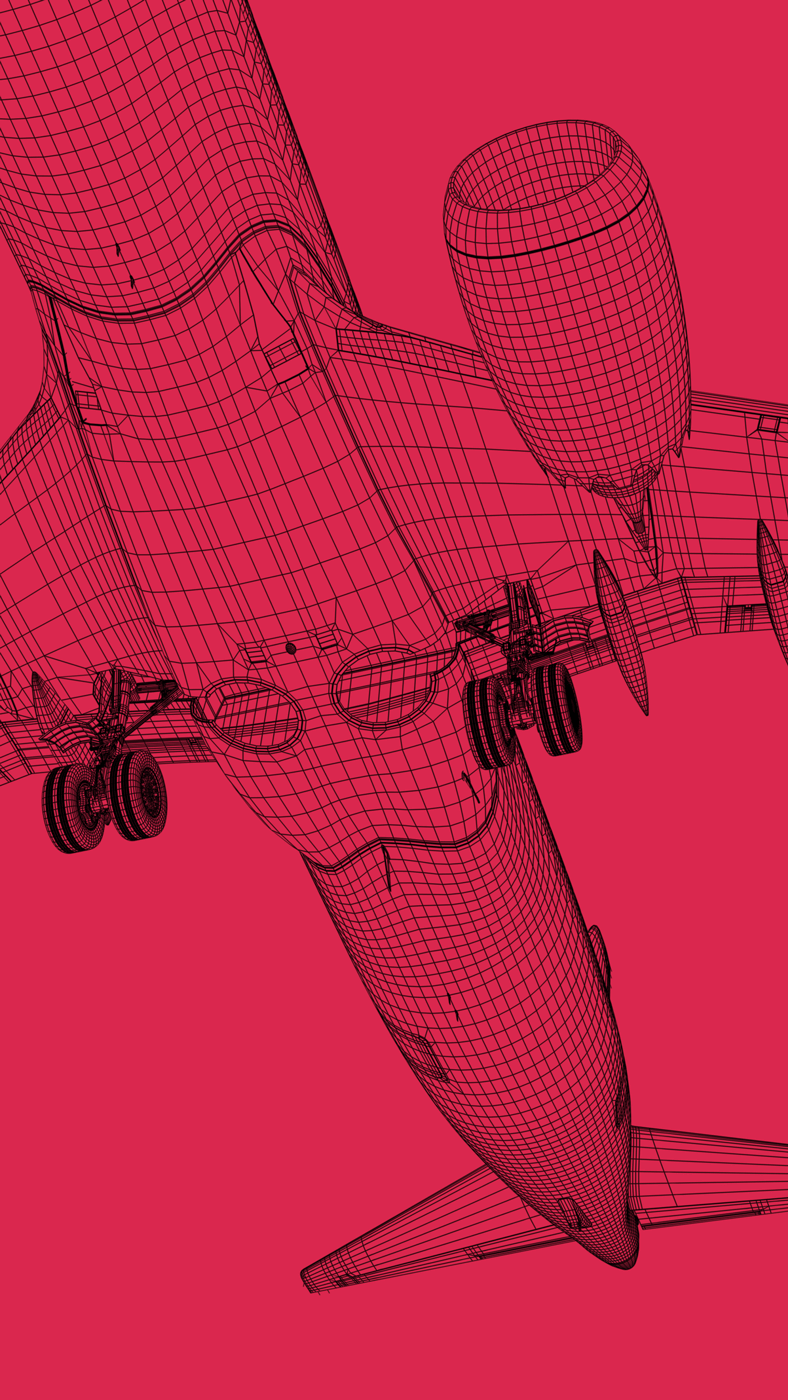

SUPPORTING THE FUTURE OF THE AEROSPACE INDUSTRY

Carpenter Technology has helped shape moments in aviation history. From the Wright Brothers’ maiden voyage of the Kitty Hawk to exploring the depths of space, our sustainable solutions are ready to take on the next challenge for the aerospace industry: climate action.

We partner with our customers on their efforts to lead on sustainability, create competitive advantage, and build value for all stakeholders. As the aerospace industry evolves, we are positioned to develop solutions assisting the expanding use of sustainable aviation fuels (SAF), testing hydrogen-powered aircraft in next-generation engine platforms, development of open architecture engines, supporting e-taxi technologies, creating new aviation technologies such as eVTOL, and more.

As a key partner of the aerospace industry, we are committed to supporting customer sustainability efforts and sustainable supplier strategies.

.png)