FROM FIRST FLIGHT

TO INFINITE HEIGHTS

The future of aerospace with advanced alloys

Materials trusted on

100% of aircraft in flight

Broadest portfolio

of aerospace alloys

135+ years of pushing

what’s possible

APPLICATION SPOTLIGHT

AEROSPACE

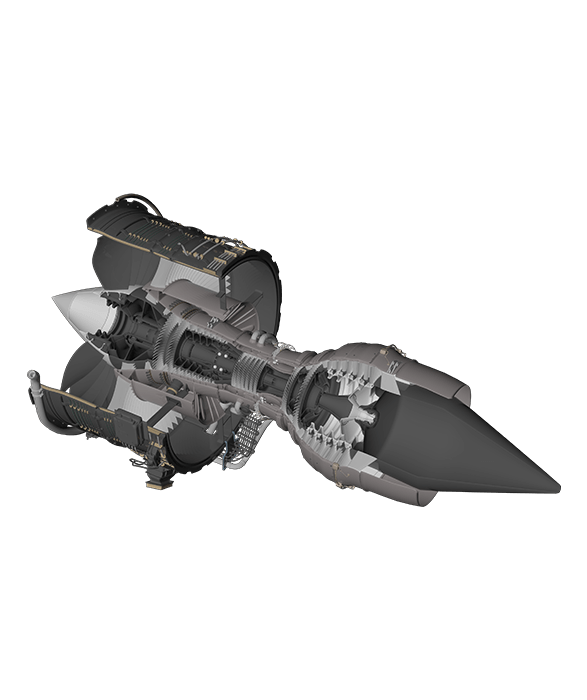

Engine Casings, Rings, & Vanes

These non-rotating critical components must operate in extremely high temperatures while maintaining their strength.

FEATURED PRODUCTS

none

718

Precipitation-hardened, nickel-base alloy that offers exceptionally high yield, tensile and creep-rupture properties up to 1300°F (704°C)

none

Waspaloy

Precipitation-hardening, nickel-base alloy with good strength and corrosion resistance with high creep resistance and grades for elevated temperature tensile strength

none

Thermo-Span®

Low coefficient of thermal expansion over a broad temperature range

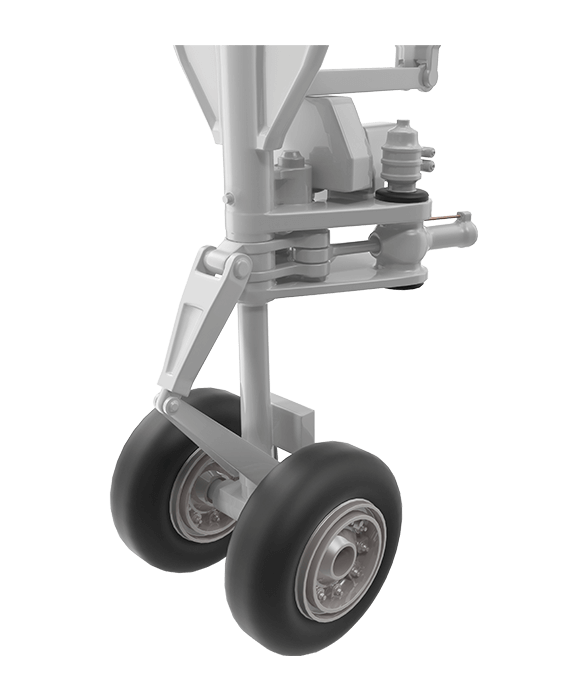

Structural Landing Gears

Customers require materials that can reliably withstand stresses induced under severe conditions. We offer a range of materials key to landing gear applications.

FEATURED PRODUCTS

none

300M

Modified 4340 steel for higher tempering temperatures possessing high hardenability and strength with good ductility and toughness in heavy sections

none

Aermet® 100

High hardness and strength combined with exceptional ductility, high fracture toughness, and exceptional stress corrosion cracking resistance in extreme temperatures

none

Ferrium® M54®

Ultra-high-strength steel with high toughness and resistance to stress corrosion cracking

none

Custom 465®

Best-in-class high-strength stainless steel to withstand high torques in harsh environments for extended periods of time with superior corrosion resistance

none

Ferrium® S53®

Ultra-high-strength steel with good toughness and temperature resistance with the added benefit of atmospheric corrosion resistance

Airframe Fasteners

Fasteners add weight. On aircraft, the strength to weight ratio is critical. Meanwhile, quality is essential in no-fail situations that include temperature extremes, high pressures, stress and weight loads, and corrosion.

FEATURED PRODUCTS

none

Ti 6Al-4V

A fully heat treatable workhorse alloy performing at temperatures up to 650°F (350°C) offering strength with light weight and corrosion resistance

none

Ti SmartCoil

Provides greater processing efficiency compared to other materials, reducing scrap waste by 20% or more

none

718

A precipitation hardenable nickel-base alloy with exceptionally high yield, tensile, and creep-rupture properties at temperatures up to 1300°F (704°C) for fatigue resistance

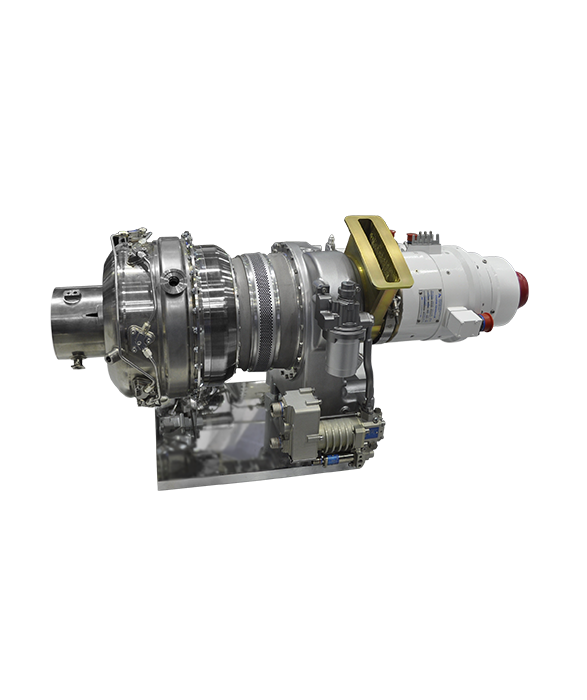

Generator Systems and Auxiliary Power Units (APUs)

High-performance materials enable the design of smaller, lightweight motors and lightweight instrumentation without compromising on performance. Our materials enable the most power-dense and smallest and lightest generators and APUs.

FEATURED PRODUCTS

none

Hiperco® 50A

Highest magnetic saturation with low coercivity and the lowest losses with mechanical properties that help optimize power dense motors and generators

none

Hiperco® 50

Highest magnetic induction and low losses with mechanical properties that can work to meet both stator and rotor application needs

none

Hiperco® 50HS

Highest magnetic saturation with high yield strength, moderate core loss, and mechanical properties that help optimize power-dense motors

none

Hypocore®

Combination of high magnetic induction and low losses for higher continuous power with low cobalt composition and low coercivity

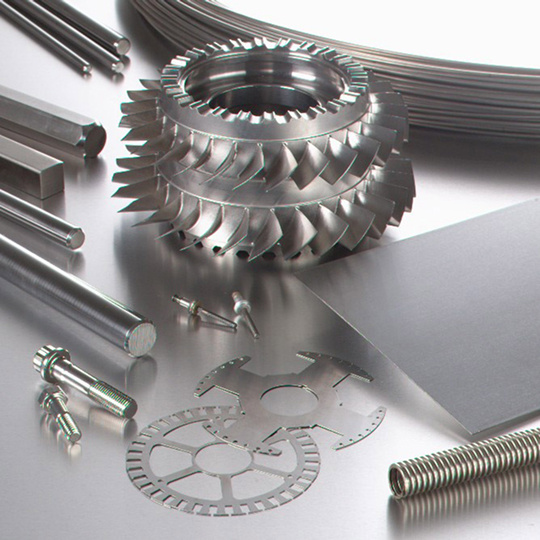

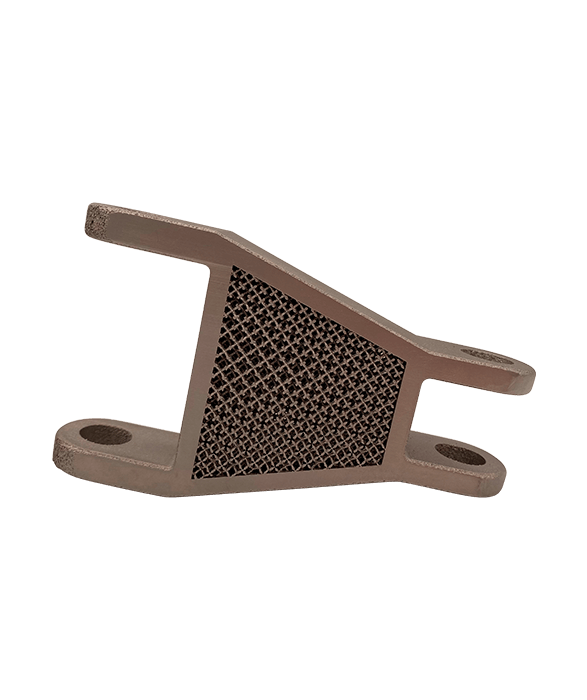

End-to-End Production

Partner with us for next-generation components created in our production facilities with powder lifecycle management and risk mitigation. Our end-to-end expertise in additive manufacturing enables us to consult at any stage in the process, adding value to your current additive manufacturing processes.

FEATURED PRODUCTS

none

Ti 6Al-4V Wire

A fully heat treatable workhorse alloy performing at temperatures up to 650F° (350°C) offering strength with light weight and corrosion resistance

none

Ti 64Al-4V ELI Grade 23+

Ti64 Grade 23+ combines controlled powder chemistry with lower oxygen content and optimized print parameters to provide 15-20% improvement in mechanical properties

When performance is on the line, it pays to spec the best. Find out how Carpenter Technology materials can help your aircraft designs and bottom lines take flight.